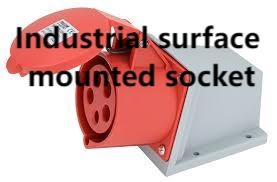

In large scale production environments and complex infrastructure projects, safe and efficient power access is a non negotiable requirement. Selecting the correct connection equipment directly affects workflow continuity and operational safety. A carefully engineered Industrial surface mounted socket provides accessible and durable wall mounted power distribution, and a high quality Industrial surface mounted socket from nante can significantly enhance reliability in demanding industrial settings. By focusing on structural strength, certified safety, and installation flexibility, businesses can build electrical systems that support continuous growth.

1. Built for Heavy Duty Performance

Industrial environments present unique challenges that ordinary electrical accessories cannot withstand. Machinery vibration, airborne particles, oil exposure, and temperature fluctuations all test the durability of power outlets. For this reason, heavy duty materials and reinforced structural designs are essential.

Premium surface mounted sockets are typically constructed from high impact thermoplastic or corrosion resistant metal enclosures. These materials prevent cracking, deformation, and premature aging. In areas exposed to mechanical stress, reinforced housing prevents loosening or displacement during daily operations.

Contact components inside the unit must also maintain consistent conductivity. High quality copper alloys are often selected for their superior electrical performance and resistance to oxidation. When combined with secure internal fastening systems, these materials ensure stable current flow even during extended operation cycles.

By choosing robustly engineered power outlets, facility managers reduce maintenance frequency and minimize unexpected interruptions that could impact productivity.

2. Advanced Electrical Protection and Compliance

Safety remains the cornerstone of every industrial installation. Electrical accessories must comply with internationally recognized standards for insulation, grounding continuity, and flame resistance. Proper insulation safeguards workers from accidental contact with live components, while effective grounding channels excess current away from sensitive equipment.

Modern designs incorporate protective shutters and sealed cable entries to prevent dust or moisture from entering the housing. These protective measures are particularly important in factories with high particulate levels or humid working conditions.

Clear terminal labeling also supports accurate wiring during installation. Reducing the likelihood of incorrect connections lowers the risk of short circuits or overheating. In high load applications, well designed ventilation paths help dissipate heat, preserving internal components and extending service life.

When professional grade equipment is installed according to recommended procedures, it forms a dependable foundation for safe and efficient industrial operations.

3. nante Industrial surface mounted socket Innovation and Craftsmanship

Precision manufacturing determines whether an electrical component performs reliably over time. nante emphasizes strict quality control protocols throughout production, ensuring each unit meets defined performance benchmarks. From raw material inspection to final assembly verification, every stage is carefully monitored.

Engineering teams focus on optimizing structural balance between durability and ease of installation. Mounting brackets are designed to provide firm wall attachment, reducing the risk of movement caused by vibration. Cable entry points are shaped to simplify routing while preserving protective sealing.

Extensive durability testing simulates real world conditions such as impact, temperature variation, and prolonged electrical load. These tests verify that the socket maintains consistent contact pressure and structural integrity. By combining thoughtful design with rigorous validation, manufacturers deliver solutions that align with modern industrial expectations.

4. Flexible Applications Across Industries

Surface mounted power outlets are valued for their adaptability. They can be installed directly onto walls, steel frames, equipment panels, or temporary structures without extensive structural modification. This flexibility supports evolving production layouts and expansion projects.

Manufacturing plants rely on these sockets to power assembly lines and automated machinery. Warehouses use them to connect charging stations and material handling equipment. Construction sites depend on them for portable tools and temporary electrical networks. Even energy facilities utilize such units to support auxiliary systems.

Because they are externally mounted, inspections are straightforward and maintenance procedures are simplified. If relocation becomes necessary, the unit can be repositioned with minimal disruption. This practical adaptability makes them an essential component of dynamic industrial environments.

Selecting the appropriate voltage and current rating ensures compatibility with operational requirements. Matching technical specifications to equipment demand prevents overload scenarios and protects both infrastructure and personnel.

5. Installation Guidance and Preventive Maintenance

Correct installation practices significantly influence long term performance. Before mounting the unit, installers should confirm that the surface is stable and capable of supporting the enclosure securely. Appropriate fastening hardware ensures firm attachment.

Cable preparation must be performed carefully to maintain conductor integrity. Proper stripping length and secure terminal tightening guarantee reliable electrical contact. Using torque controlled tools prevents both over tightening and loose connections.

Routine inspections help identify early signs of wear or environmental impact. Checking for discoloration, corrosion, or loose fittings allows maintenance teams to address potential issues proactively. Cleaning the exterior housing prevents dust accumulation that could interfere with sealing mechanisms.

In environments with high humidity, monitoring for condensation inside the enclosure is recommended. Maintaining dry internal conditions preserves insulation performance and reduces long term degradation risks. A structured maintenance schedule supports consistent operational safety and extends the lifecycle of electrical components.

Reliable power connectivity supports the efficiency and safety of modern industrial facilities. By emphasizing structural durability, certified protection, and proper installation methods, organizations can ensure stable energy distribution across diverse applications. Investing in carefully engineered solutions contributes to productivity and long term infrastructure resilience. For additional professional insights and installation recommendations, please visit https://www.nante.com/news/industry-news/nante-announces-practical-guidance-for-industrial-surface-mounted-socket-installations.html to access detailed industry guidance and technical perspectives.