In the rapidly advancing frozen dessert manufacturing industry, producers are under increasing pressure to deliver consistent quality, diverse product structures, and large-scale output—all while maintaining strict hygiene and cost efficiency. The Rollo Stick Ice Cream Machine is engineered to meet these demands at an industrial level, offering unmatched performance for layered ice creams, chocolate-coated products, and high-volume stick formats.

As a specialized equipment manufacturer with years of expertise in ice cream machinery, Wuxi Danxiao integrates advanced refrigeration engineering, precision automation, and food-grade design principles into each Rollo machine. The result is a production platform capable of delivering stable performance at output ranges of 3,000 pcs/h, 6,000 pcs/h, 12,000 pcs/h, and 18,000 pcs/h, supporting both medium-scale plants and large global producers.

1. Industrial Output Designed for Scalable Production

The Rollo Stick Ice Cream Machine is configured to support multiple production capacities, ensuring manufacturers can match equipment performance with market demand:

-

3,000 pcs/h: Suitable for regional or specialty production

-

6,000 pcs/h: Ideal for growing mid-sized factories

-

12,000 pcs/h: Supports national distribution scale

-

18,000 pcs/h: Designed for multinational production and continuous operation

By offering multiple output levels, Wuxi Danxiao enables factories to expand capacity without changing operational workflows or product specifications.

2. Structural Engineering for Stable, Continuous Operation

2.1 High-Efficiency Freezing Channel

At the core of the machine lies a precision-controlled freezing tunnel capable of rapidly reducing product temperature while maintaining exceptional uniformity.

Key engineering features include:

-

Stable crystallization for smooth texture

-

Optimized heat-exchange surfaces for consistent freezing

-

Uniform cavity hardness essential for stick insertion

This guarantees that every ice cream, regardless of its position in the mold plate, achieves identical freeze profiles.

2.2 Automated Stick-Placement System

The machine incorporates a high-speed robotic stick applicator that ensures:

-

Centered stick placement

-

Accurate insertion depth

-

Real-time timing synchronization with the freezing cycle

This precision directly affects product geometry and consumer-quality perception, making automated control essential for high-value production.

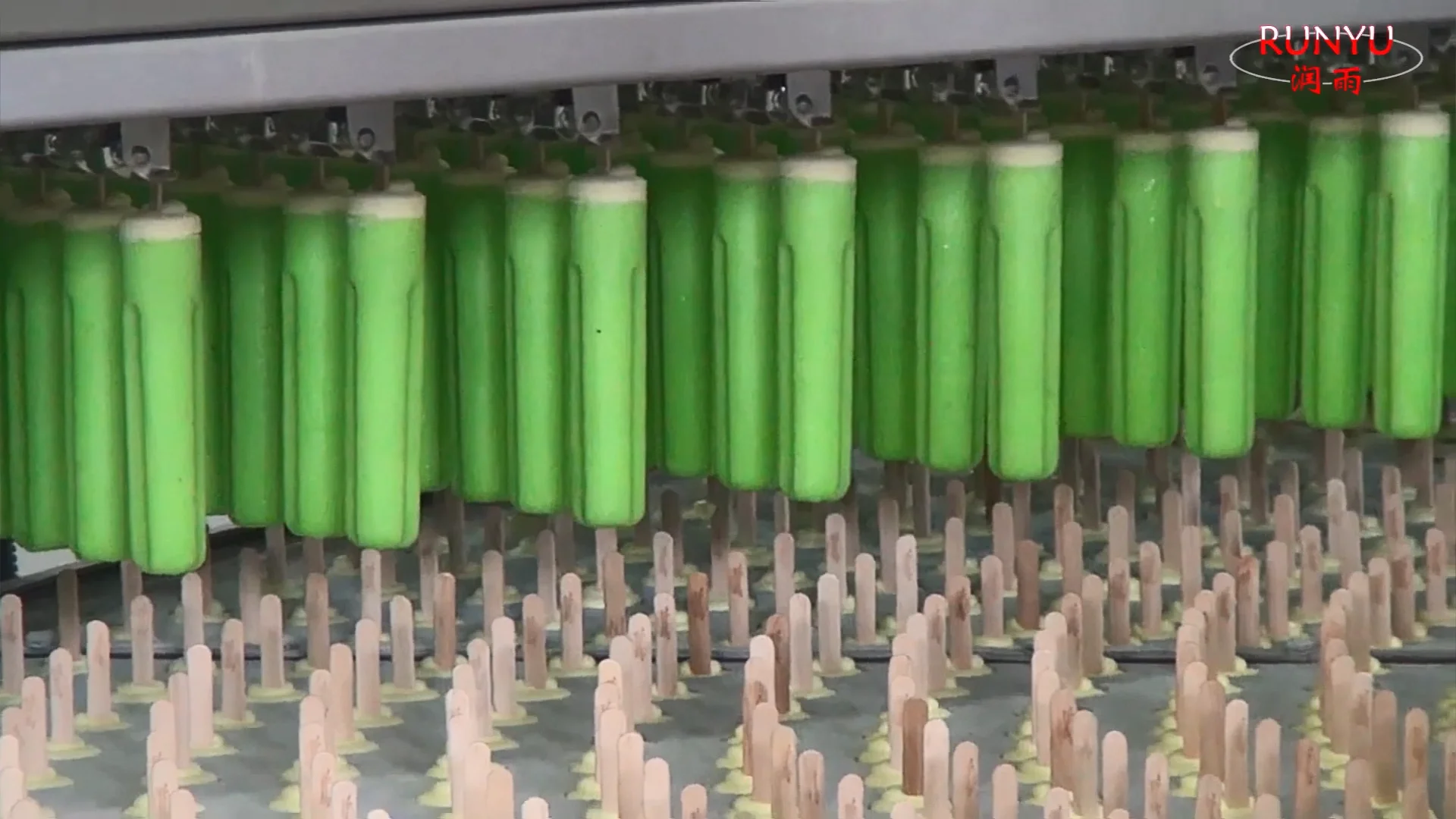

2.3 Reliable Demolding Mechanics

The demolding system utilizes controlled thermal release, minimizing stress on the frozen core.

Advantages include:

Crack-free extraction

Damage-free handling for layered or coated products

Consistent output even during peak-speed runs

This stability is particularly important when producing products with multiple layers or delicate chocolate shells.

3. Built for Layered and Chocolate-Coated Ice Cream Production

Modern consumers increasingly demand premium-style stick ice creams with distinctive layers, fillings, and coatings.

The Rollo machine accommodates this trend through:

3.1 Multi-Stage Dosing for Layered Products

With programmable dosing heads, the system supports:

-

Dual-flavor constructions

-

Ripple and variegate effects

-

Filled centers

-

Precision-layered structures for visual appeal

Each dosing sequence is synchronized with mold indexing to ensure layer accuracy down to the millimeter.

3.2 Chocolate Dipping Integration

The optional chocolate dip system maintains strict temperature and viscosity control, producing:

-

Smooth, glossy coating

-

Even distribution around the product

-

Adjustable dipping depth for customized shell thickness

This module allows producers to differentiate products and address premium-market segments.

4. Food-Safety Engineering and Hygienic Construction

Every component of the Rollo Stick Ice Cream Machine adheres to strict food-industry standards. Wuxi Danxiao ensures:

-

Stainless-steel frames and food-contact surfaces

-

CIP-compatible (Clean-In-Place) pipelines

-

Hygienic structural design with no dead corners

-

Compliance with international sanitation criteria including HACCP and ISO22000

This makes the machine suitable for global food production environments.

5. Intelligent Controls and Automation for Modern Production Lines

The machine features an advanced PLC-based control platform with:

-

Real-time temperature monitoring

-

Automated fault detection and alarms

-

Product recipe management

-

Touchscreen interface for user-friendly operation

This digital architecture reduces operator workload, minimizes human error, and improves consistency in 24/7 production environments.

6. Why Manufacturers Trust Wuxi Danxiao Rollo Machines

Wuxi Danxiao’s long-term focus on ice cream production equipment has resulted in a deep understanding of frozen-dessert manufacturing challenges.

Customers benefit from:

-

Equipment engineered for longevity and continuous-load operation

-

Uniform product quality across all cavities and cycles

-

Highly scalable machine design

-

Comprehensive technical support and tailored solutions

For manufacturers seeking high-volume output without compromising quality, the Rollo Stick Ice Cream Machine represents a forward-looking, reliable production investment.

Conclusion

As product innovation continues to define the competitive landscape of the global ice cream market, the Rollo Stick Ice Cream Machine stands as a versatile, high-capacity solution engineered for precision, hygiene, and long-term operational stability. Through advanced freezing technology, automated handling, layered production capabilities, and rigorous mechanical design, the system offers manufacturers a clear advantage in producing modern, high-value stick-based ice creams. Backed by the engineering expertise of Wuxi Danxiao, producers can scale confidently while delivering consistent, premium-quality frozen treats to markets worldwide.