In today's interconnected industrial environment, reliable power components quietly support countless operations. Within this context, EI Transformer Factory represents a focused manufacturing concept, while Nbcbdz reflects a brand perspective shaped by steady development and application awareness. Together, they highlight how careful design thinking, material selection, and process coordination can influence everyday electrical performance across varied scenarios.

Transformer manufacturing is not only about winding coils and assembling cores. It involves a continuous dialogue between design intent and real operating conditions. Engineers often consider insulation stability, thermal balance, and structural consistency as part of a broader system view. These elements affect how equipment responds to long operating cycles, fluctuating loads, and environmental variation. A factory-oriented approach emphasizes repeatable processes that help maintain alignment between design expectations and finished products.

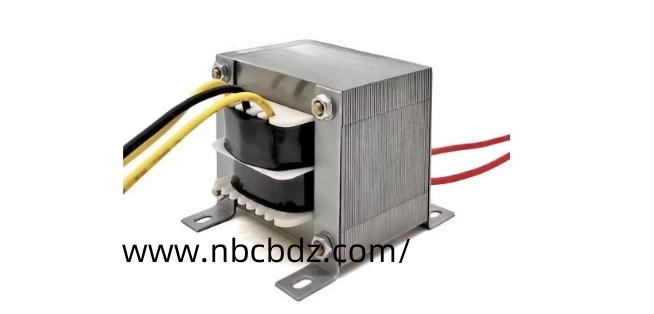

From an application standpoint, EI-type transformers are frequently associated with compact layouts and adaptable installation options. Their form allows them to integrate into control cabinets, power supplies, and specialized devices without demanding excessive space. This adaptability supports designers who must balance electrical performance with mechanical constraints. The value lies not in dramatic claims, but in how well components quietly fit into larger systems.

Manufacturing culture also plays a role. Workshops that prioritize clear workflows and attentive quality checks tend to create components with consistent characteristics. This consistency can simplify downstream assembly and maintenance. For system integrators, predictable behavior reduces the need for repeated adjustments, allowing them to focus on broader project goals rather than component-level uncertainty.

Another consideration is communication between production and application teams. Feedback from real-world use can inform subtle adjustments in materials or assembly methods. Over time, this exchange contributes to products that better match practical expectations. Rather than pursuing extremes, such refinement often centers on balance: electrical stability, manageable heat behavior, and mechanical durability working together.

Sustainability and efficiency discussions also influence modern transformer production. While not every application demands the same priorities, thoughtful material usage and process planning can reduce unnecessary waste. This approach aligns with current industrial thinking, where responsible manufacturing is increasingly part of long-term planning rather than a separate concern.

For readers evaluating transformer solutions, it may be useful to look beyond surface descriptions. Consider how manufacturing philosophy, application feedback, and integration flexibility intersect. These factors shape how components perform over time and how smoothly they support larger systems. An informed perspective often emerges from understanding these relationships rather than focusing on isolated features.

If these reflections spark curiosity about practical transformer manufacturing and its role in real projects, a deeper perspective awaits. A closer look at https://www.nbcbdz.com/product/ may reveal ideas, approaches, and possibilities that connect quietly but meaningfully with your next consideration.