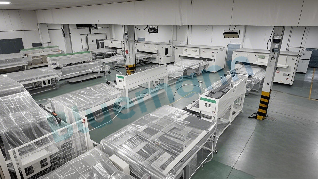

In high-speed production lines, precise handling of materials and components is critical. Manual flipping of items can introduce inefficiencies, errors, and safety risks. The 180° Flip machine, engineered by Bluemann, addresses these challenges by automating the flipping process with precision, reliability, and compact design.

Bluemann integrates advanced mechanical engineering, ergonomic operation, and LED-based inspection technology, making this machine ideal for modern production environments where space efficiency, operational safety, and productivity are paramount.

Key Technical Features

The 180° Flip machine is designed to maximize performance while maintaining simplicity and reliability.

1. LED-Assisted Inspection

Equipped with front and rear LEDs, ensuring optimal illumination for operators.

Facilitates visual inspection, quality control, and quick detection of material defects.

Enhances employee safety and minimizes operational errors during flipping processes.

2. Compact Footprint

The machine occupies minimal space, making it suitable for factories with limited floor area.

Small size does not compromise performance, allowing integration into existing production lines without requiring extensive reconfiguration.

3. Simple and Reliable Operation

The control interface is designed for user-friendly operation, reducing training time for operators.

Reliable mechanisms ensure consistent 180° rotation, maintaining product integrity.

Durable construction materials minimize maintenance requirements and prolong service life.

Operational Efficiency and Ergonomics

1. Workflow Integration

The 180° Flip machine can be seamlessly integrated into conveyor lines, pick-and-place systems, and automated inspection stations.

Reduces manual handling steps, thereby improving overall production speed and consistency.

2. Employee-Friendly Design

LEDs improve visibility, minimizing operator strain.

Intuitive operation panel allows quick adjustments and routine checks without technical complexity.

Ergonomic positioning reduces repetitive motion injuries, enhancing workplace safety.

3. Precision and Reliability

Each flip is accurately controlled, reducing risk of product misalignment or damage.

High repeatability ensures uniform handling, critical for assembly, packaging, and inspection processes.

Applications Across Industries

The versatility of the 180° Flip machine allows its adoption in multiple industrial sectors:

1. Electronics Manufacturing

Flipping printed circuit boards (PCBs) during assembly or inspection.

Ensures sensitive components remain undamaged during rotation.

2. Packaging Industry

Automates turning of cartons, bottles, or containers for labeling, printing, or quality checks.

Reduces labor costs while increasing throughput.

3. Pharmaceutical and Medical

Handles vials, syringes, or small containers requiring 180° rotation for inspection or processing.

Supports high hygiene standards due to minimal human contact.

4. Food and Consumer Goods

Flips trays, boxes, or other packaged goods for quality verification and coding.

Compact size allows integration into high-density production lines.

Advantages of Choosing Bluemann

Bluemann differentiates its 180° Flip machine through several key strengths:

1. Space-Saving Design

Ideal for factories with restricted space.

Enables multi-machine setups without crowding production floors.

2. Enhanced Inspection Capability

LED illumination at both sides supports rapid and accurate inspection, reducing defective outputs.

Simplifies compliance with quality assurance protocols.

3. Ease of Operation

Minimal training required for operators.

Simplified controls reduce operational errors and downtime.

4. Maintenance and Durability

Sturdy components ensure long-term operation with minimal maintenance.

Reduced mechanical complexity decreases the frequency of service interventions.

5. Cost-Effective Automation

Offers high ROI by combining automation, precision, and compact design.

Reduces labor costs, human error, and production bottlenecks simultaneously.

Conclusion

The 180° Flip machine by Bluemann represents the convergence of compact design, precision engineering, and user-centric operation.

By integrating LED-assisted inspection, space-efficient construction, and simple yet reliable control mechanisms, it ensures high-speed production, enhanced quality, and reduced operational risk. Whether for electronics, pharmaceuticals, food, or packaging industries, Bluemann’s solution empowers manufacturers to maximize efficiency while minimizing costs and errors.

https://www.bluemannsolar.com/compact-and-reliable-bluemann-s-smart-flip-automation-solution.html