The global ice cream industry continues to evolve toward higher productivity, stronger product consistency, and greater flexibility in product design. As consumer demand shifts toward variety—multicolor swirls, layered flavors, filled centers, and decorative toppings—manufacturers require equipment capable of meeting these complex production needs without compromising accuracy or hygiene. The cup and cone filling machine, developed by Wuxi Danxiao, represents a specialized automation solution engineered to support high-speed, high-precision ice cream production in modern industrial environments.

1. Intermittent-Type Linear-Movement Architecture: A Foundation of Precision

At the core of the machine’s design is its intermittent-type linear movement system. Unlike continuous-motion systems that operate at constant flow, intermittent linear movement allows the system to stop at exact index positions during each filling cycle. This provides several engineering advantages:

High positional accuracy, essential for cone or cup alignment

Stable filling trajectories, preventing overflow or asymmetrical deposition

Improved compatibility with multi-head filling configurations

The precision alignment mechanism ensures that each cup or cone reaches the exact filling point, which is critical for maintaining uniform height, pattern consistency, and a clean product appearance.

Wuxi Danxiao optimizes the indexing mechanism to ensure smooth acceleration and deceleration, reducing spillage and mechanical stress during high-speed operations.

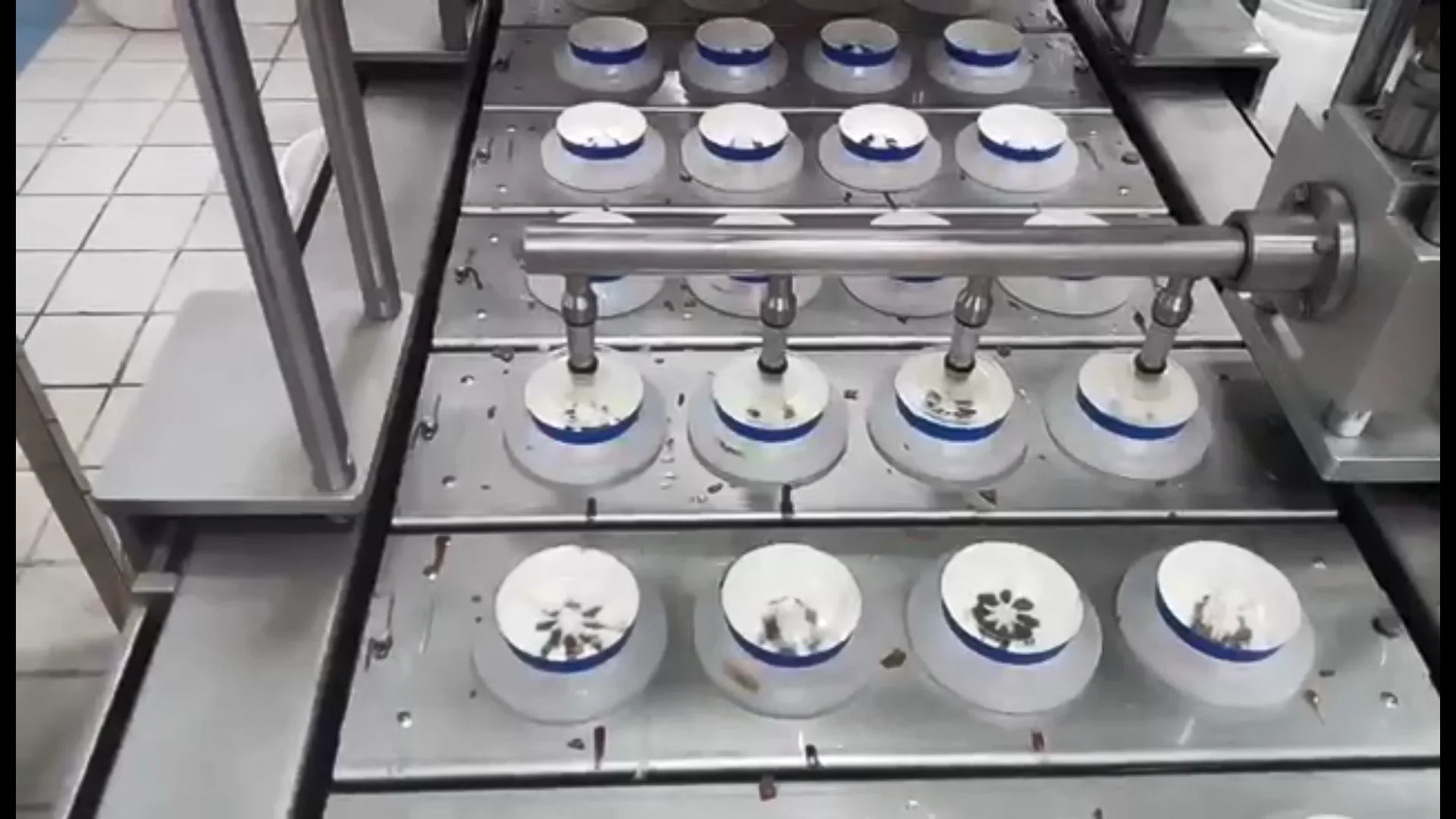

2. Multi-Head Filling System: High Output and Diverse Product Capability

One of the defining characteristics of the cup and cone filling machine is its multi-head filling system, which can be customized according to production capacity and product types. The multi-head system allows simultaneous dispensing of multiple servings during each cycle, significantly improving output per minute.

Depending on configuration, the system can handle:

Standard single-flavor ice creams

Double-color and triple-color swirl ice creams

Layered, center-filled, or decorative products

Cone ice creams with controlled tip filling

Cups with precise top-level shaping

The machine’s nozzles, valves, piston pumps, and dispensing heads are engineered to maintain consistent product texture and density, even when processing higher-viscosity ice cream mixes.

3. Advanced Decorating and Pattern-Forming Capabilities

Beyond basic filling, modern frozen dessert manufacturing requires equipment capable of producing visually attractive and complex patterns. Wuxi Danxiao integrates specialized decorating functions into the machine, enabling the creation of:

Garland-style patterns

Rotary swirl formations

Vertical or horizontal layered structures

Chocolate or jam injection patterns

This is achieved through precise control of rotational actuators, pressure-regulated dosing pumps, and synchronized dispensing timing. The machine’s rotating nozzles can create intricate designs while maintaining uniform volume control.

These capabilities allow manufacturers to expand product lines without investing in entirely new equipment.

4. Jam and Chocolate Injection: Enhanced Sensory Profiles

To meet the growing demand for multi-layer flavors and filled ice creams, the machine supports integrated jam and chocolate injection. This module includes:

Independent storage tanks

Temperature-controlled pipelines (critical for chocolate viscosity)

Auxiliary dosing valves

Sanitary-grade delivery pathways

This design ensures that inclusions such as fruit jam, chocolate paste, caramel, or flavored syrups are deposited with precise volume and location control. Injection can occur at the center, near the core, or at multiple height levels within the cup or cone.

This functionality enables products such as:

Chocolate-core cones

Three-layer cup desserts

Ripple-style fruit ice creams

Without compromising production speed.

5. Compatibility with Plane Cutting Products

Another advanced feature is the ability to produce plane cutting products, where ice cream is filled to a flat surface and then cut cleanly using a mechanical blade or wire. This is often used for products that require:

Smooth, uniform surfaces

Accurate volume control

Ready-to-pack dessert cups

The cutting system maintains consistency even during rapid cycle times, reducing manual intervention.

6. Hygienic Design and Easy Maintenance

Wuxi Danxiao integrates hygienic engineering principles into the machine’s construction, including:

Food-grade stainless steel contact surfaces

CIP (Clean-in-Place) compatibility

Smooth internal piping for low bacterial adhesion

Tool-free nozzle disassembly

The machine’s modular design allows quick maintenance, routine inspection, and rapid component replacement—ideal for factories operating multiple production shifts.

7. Applications Across Ice Cream Production Lines

The cup and cone filling machine is commonly used in:

-

Industrial ice cream factories

-

High-volume dairy product plants

-

Frozen dessert co-packing facilities

-

Soft and hard ice cream production lines

It can be integrated with upstream and downstream systems, including:

-

Cone dispensers

-

Cup denesters

-

Freezing tunnels

-

Packaging machines

-

Conveyor-based distribution systems

This makes it a central component of automated ice cream production.

Conclusion: A Complete Filling Solution for Modern Ice Cream Manufacturing

The cup and cone filling machine by Wuxi Danxiao is engineered to deliver a combination of accuracy, versatility, and high-speed automation. With its intermittent linear movement structure, multi-head filling system, advanced patterning capabilities, jam/chocolate injection modules, and hygienic design, it supports a broad range of ice cream products without requiring separate production lines.

For processors seeking equipment that balances efficiency with product creativity, Wuxi Danxiao provides one of the most adaptable solutions in the frozen dessert machinery sector.