Introduction: Importance of Contact and Insulation Resistance

Electrical performance is a critical factor in the design of wire-to-board connectors. The WTB Wire to Board Connector is engineered to provide reliable and stable electrical connections between wires and printed circuit boards. Two key parameters that define its performance are contact resistance and insulation resistance. Contact resistance ensures efficient current flow between mating contacts, while insulation resistance prevents leakage and short circuits. Understanding these characteristics is essential for designers and engineers seeking dependable connectivity solutions.

Contact Resistance: Ensuring Efficient Current Flow

Contact resistance refers to the resistance encountered at the interface between the connector’s pins and mating terminals. Low contact resistance is essential for efficient current transmission, reducing heat generation and preventing energy loss. The WTB Wire to Board Connector is designed with precision contacts made from high-conductivity materials, often plated with gold or tin, to maintain minimal resistance. This ensures stable electrical performance even under repeated insertion and withdrawal cycles. Low and consistent contact resistance is particularly important in high-current or sensitive signal applications, where voltage drops or signal degradation must be minimized.

Insulation Resistance: Preventing Leakage and Short Circuits

Insulation resistance measures the ability of the connector to resist unwanted current flow between adjacent conductors or to the connector housing. A high insulation resistance is critical for preventing leakage currents, short circuits, and potential device failures. The WTB Wire to Board Connector uses high-quality insulating materials such as reinforced plastics or engineered polymers to maintain strong dielectric properties. These materials ensure that the connector performs reliably under varying environmental conditions, including humidity, temperature changes, and vibration.

Factors Affecting Electrical Resistance

Several factors can influence the contact and insulation resistance of a WTB Wire to Board Connector. Proper mating and alignment of contacts, adequate insertion force, and clean surfaces all contribute to low contact resistance. For insulation resistance, environmental exposure, contamination, or physical damage can reduce effectiveness. The connector’s design, including contact geometry, plating, and insulating material selection, plays a crucial role in ensuring consistent electrical performance.

Testing and Reliability Standards

Manufacturers of WTB Wire to Board Connectors typically conduct rigorous testing to verify contact and insulation resistance. These tests often follow industry standards, such as IEC or UL specifications, measuring resistance under various temperatures, humidity levels, and mechanical stresses. Connectors that meet these standards provide engineers with confidence that their systems will operate reliably over the product’s lifecycle, even in demanding applications like automotive, industrial, or consumer electronics.

Reliable Electrical Performance

In conclusion, the WTB Wire to Board Connector demonstrates excellent contact and insulation resistance, ensuring efficient current flow and preventing electrical leakage. Its precision contacts, high-quality conductive plating, and robust insulating materials contribute to consistent and reliable performance. For designers and engineers, understanding these characteristics is essential when selecting connectors for applications requiring dependable electrical connections under various environmental and operational conditions. With proper design and maintenance, this connector provides a stable and trustworthy solution for modern electronics.

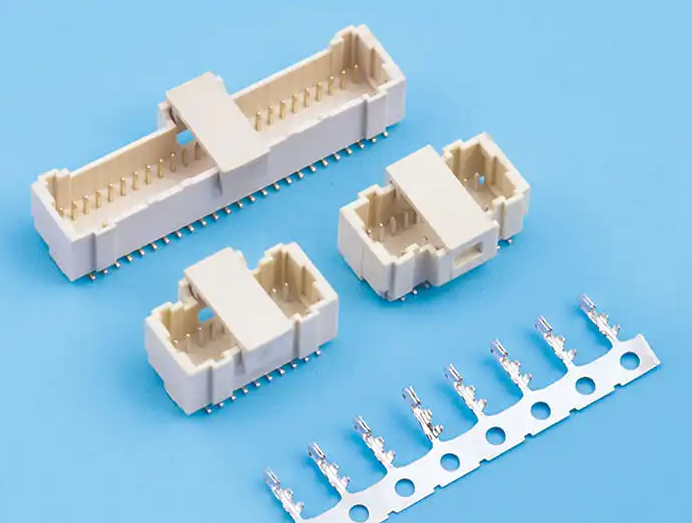

1、CKT: 2Pin to 26Pin

2、Current rating: 1A AC/DC

3、Voltage rating(max): 50V, AC/DC

4、Working Temperature: -25°C~+85°C,

(Including temperature rise in applying electrical current)

5、Contact resistance: Initial value S20mΩ

After environmental testing≤30mΩ

6、Insulation resistance: 2100MΩ

7、Withstand voltage: 500VAC(rms)

8、Applicable wire: AWG #32 to #28

9、Applicable PCB board thickness: 1.6mm to 2.0mm