Packaging for specialty chocolates—especially mushroom chocolate bars—requires more precision than traditional confectionery wraps. These bars contain functional ingredients that require protection from heat, moisture, oxidation, and physical pressure. As consumer demand grows for wellness-focused treats, brands are increasingly prioritizing packaging that preserves freshness, extends shelf life, and enhances product credibility. This is where heat-resistant chocolate packaging becomes essential.

In the context of functional or infused chocolates, relying on standard wrappers is no longer enough. Many brands now choose heat-stable materials and packaging formats specifically engineered to maintain product quality during storage and shipping. This shift reflects a growing awareness that upgraded packaging not only prevents melting and deformation but also maintains the integrity of mushroom-based formulations. Using heat-resistant chocolate packaging in thoughtfully designed structures supports both safety and brand presentation.

Why Mushroom Chocolate Bars Require Specialized Packaging

Mushroom chocolate bars differ from regular chocolates in moisture sensitivity, ingredient composition, and shelf-life expectations. Adaptogenic or functional mushrooms contain bioactive compounds that may lose potency if exposed to excessive heat, humidity, or oxygen. This makes mushroom chocolate freshness packaging an important factor in product performance.

Heat exposure can cause blooming (a powdery appearance), texture changes, and separation of ingredients. Moisture can degrade both the chocolate and the functional additions within it. Proper insulation, moisture-barrier layers, and controlled-environment packaging ensure the consumer receives a bar with the intended flavor, scent, and potency. Brands also rely on custom printed chocolate bar packaging to communicate ingredients, instructions, and nutritional information clearly.

Key Features of Packaging for Mushroom Chocolate Bars

1. Heat Resistance and Thermal Stability

The core requirement is temperature resilience. Packaging materials like foil laminates, Mylar, and insulated pouches provide high-level heat protection. These materials prevent melting during shipping or warm retail environments.

2. Moisture and Oxygen Barriers

The shelf life of mushroom chocolate bars depends heavily on preventing oxidation or moisture intrusion. A multi-layer structure with aluminum or metallized film provides effective barriers against air exchange.

3. Odor and Flavor Preservation

Some mushroom varieties have distinct natural notes. Packaging must lock in flavor profiles while preventing outside odors from altering the chocolate’s taste.

4. Structural Durability

Chocolate bars are brittle. Sturdy box-style packaging helps protect against breakage. The addition of inserts or sleeves can further stabilize the bars inside retail-ready packaging.

Most Effective Materials for Mushroom Chocolate Bar Packaging

1. Foil Wrappers

Foil remains one of the strongest materials for sealing in freshness. It offers superior heat resistance and prevents aroma transfer. It also plays a major role in mushroom chocolate freshness packaging because it reduces oxidation.

2. Mylar Packaging

Mylar pouches or wrappers have gained popularity due to their thermal insulation, puncture resistance, and light-blocking properties. They can also be custom printed for branding or compliance.

3. Kraft Paper With Barrier Liners

Eco-conscious brands often choose Kraft packaging combined with an internal laminated film. This combination provides strength and sustainability while still maintaining product protection.

4. Rigid Paperboard Boxes

When the goal is a premium unboxing experience, rigid boxes with internal foil layers offer heat resistance and structural stability. They also provide space for product labeling for mushroom chocolates, which is crucial for compliance and consumer clarity.

How Product Labeling Supports Safety and Consumer Trust

Accurate and transparent labeling is essential in specialty chocolate markets. Information such as mushroom type, dosage, flavor, storage instructions, and safety disclaimers should be clearly displayed. Packaging formats like paperboard boxes or multi-layer pouches allow ample printing space for such details.

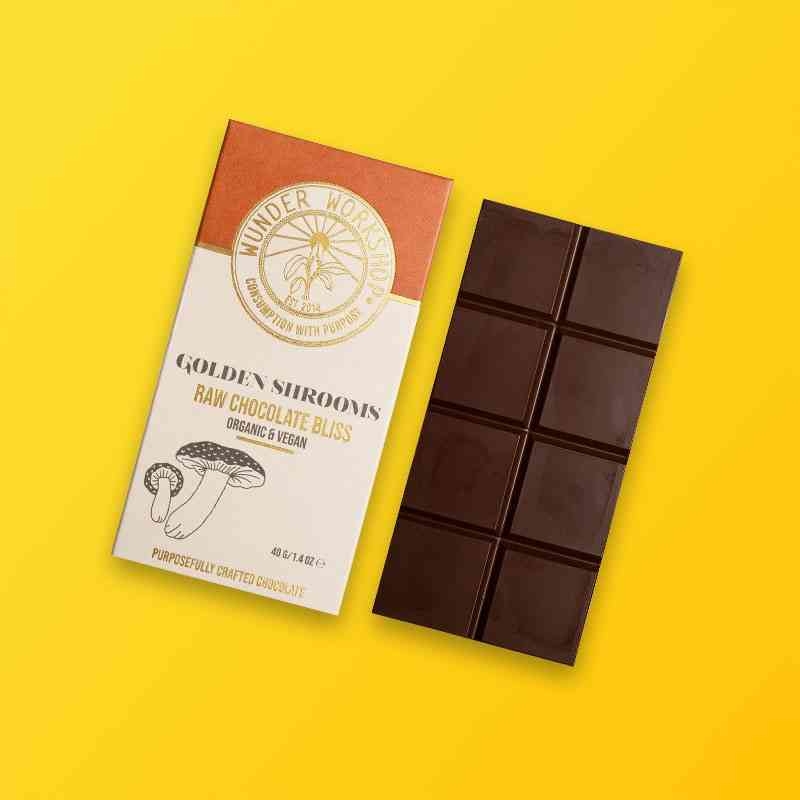

Labels also play a role in brand differentiation. With custom printed chocolate bar packaging, brands can tailor visuals to match product narratives—whether wellness-focused, luxury-themed, or nature-inspired.

Sustainability and Eco-Friendly Packaging Trends

Modern consumers increasingly favor packaging that is responsibly sourced and recyclable. In response, manufacturers are producing insulated yet eco-minded packaging solutions. Recyclable foil laminates, plant-based films, and biodegradable paper structures are becoming mainstream.

This movement complements the mushroom chocolate category well, as these products are already associated with natural wellness. Eco-forward packaging helps reinforce the consumer’s perception of quality and responsibility.

Choosing the Right Packaging Structure for Mushroom Chocolates

Different brands choose different packaging structures depending on shelf placement, shipping requirements, and brand identity. Options include:

1. Sleeve and Tray Packaging

Ideal for retail-based premium bars. Offers structural protection and ample surface area for branding.

2. Mylar Heat-Sealed Pouches

Perfect for eCommerce due to their temperature stability and compactness.

3. Folding Cartons with Inner Wraps

Combines external branding with internal protection layers.

4. Rigid Magnetic Boxes

Used for luxury mushroom chocolate gift sets.

Every structure must align with both functional needs and consumer expectations.

How Advanced Packaging Supports Brand Growth

Better packaging increases customer satisfaction. When chocolate bars arrive intact and fresh, consumers trust the brand and are more likely to repurchase. This is especially important in mushroom-based wellness markets, where product quality is closely tied to credibility.

In the evolving premium chocolate space, companies are increasingly choosing custom design packaging to strike the right balance between protection, aesthetics, and functionality. Whether the goal is improved thermal insulation or elevated presentation, tailored packaging solutions offer clear advantages. Many brands that once relied on simple wraps now recognize the importance of incorporating custom design packaging into their overall retail and shipping strategy.

Conclusion

Mushroom chocolate bars require thoughtfully engineered packaging to maintain freshness, potency, and structural integrity. From foil laminates and Mylar pouches to paperboard boxes with functional labeling, the right materials and design choices ensure safe shipping and appealing presentation. As functional foods continue to grow in popularity, packaging will remain one of the most important factors in product quality and consumer satisfaction.