In an era when sustainability is increasingly integrated into industrial practices, drilling operations are also under pressure to minimize their environmental footprint. Among various components, Button Bits present a meaningful opportunity for greener drilling, particularly Rock Button Bits, thanks to their long lifespan and efficiency. At Kaiqiu Drilling Tools Co., Ltd., innovation is not just about power; it's about responsible performance.

To start, the longevity of button bits means less frequent manufacturing, shipping, and disposal. Because Kaiqiu’s button bits are designed to handle intense abrasion and impact, they do not wear out quickly. This results in fewer bits being discarded and replaced, reducing the waste generated in drilling operations. It also lowers the carbon emissions associated with producing and transporting new bits.

Moreover, efficient rock fragmentation helps optimize energy use. Well-designed rock button bits crack and displace rock more effectively, which in turn requires fewer drilling cycles and lower air or fluid consumption. Over many drilling hours, this efficient fragmentation translates into saved fuel or electric energy, depending on the rig type — an important advantage from both environmental and cost perspectives.

Another sustainable aspect lies in maintenance. Rather than discarding a worn-out bit, drilling teams can recondition the buttons. Kaiqiu’s button bit grinder solutions or compatible regrinding services facilitate recycling of the bit’s core body, while reconstituting the tungsten-carbide buttons. This practice aligns with the principles of circular economy, reducing resource consumption and avoiding raw-material waste.

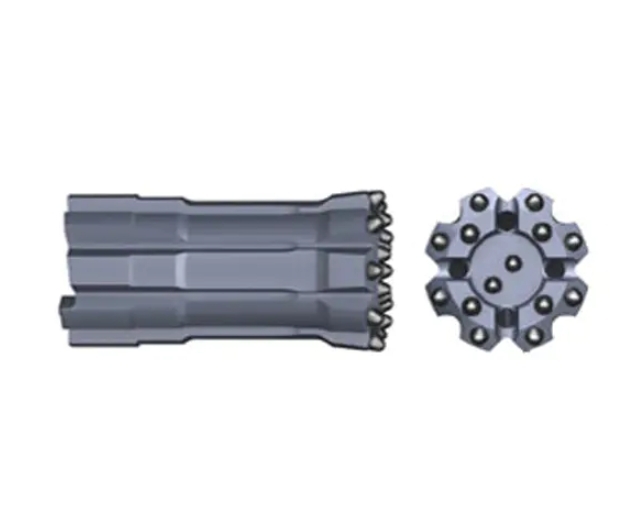

Kaiqiu also emphasizes design flexibility, offering a variety of button shapes (spherical, parabolic, etc.) and face profiles. By selecting the right configuration for a given geology, drillers can minimize over-penetration, avoid inefficient drilling, and reduce unnecessary energy usage. The result: a more precise borehole, lower machine load, and reduced environmental impact.

Finally, using higher-quality bits means fewer bit failures and associated environmental risk. A bit failure can lead to lost tools downhole or emergency interventions, which cause operational delays and may require resource-heavy retrieval efforts. By relying on robust rock button bits, these risks are lowered, improving both safety and sustainability.

In summary, the adoption of advanced button bits — especially from a manufacturer like Kaiqiu Drilling Tools Co., Ltd. — supports not only drilling productivity, but also a more environmentally responsible approach. Through durability, reconditioning, and efficient drilling design, rock button bits contribute to a more sustainable future for the drilling industry.