An Automatic Stripping Machine is now a core piece of equipment in many manufacturing lines where wire preparation needs to be fast, accurate, and consistent. From electronics production to automotive assembly, businesses rely on these machines to handle repetitive wiring tasks that once required skilled manual work. The purpose is simple: make wire processing more efficient while maintaining precision and quality.

An Automatic Stripping Machine can strip insulation from wires, cut them to specific lengths, and even crimp terminals—all in a single operation. This combination saves time and reduces handling errors. For factories managing high production volumes, such automation helps maintain a steady workflow and minimize downtime. Adjustable settings allow the machine to process wires of different diameters and materials, making it flexible enough to handle changing project requirements.

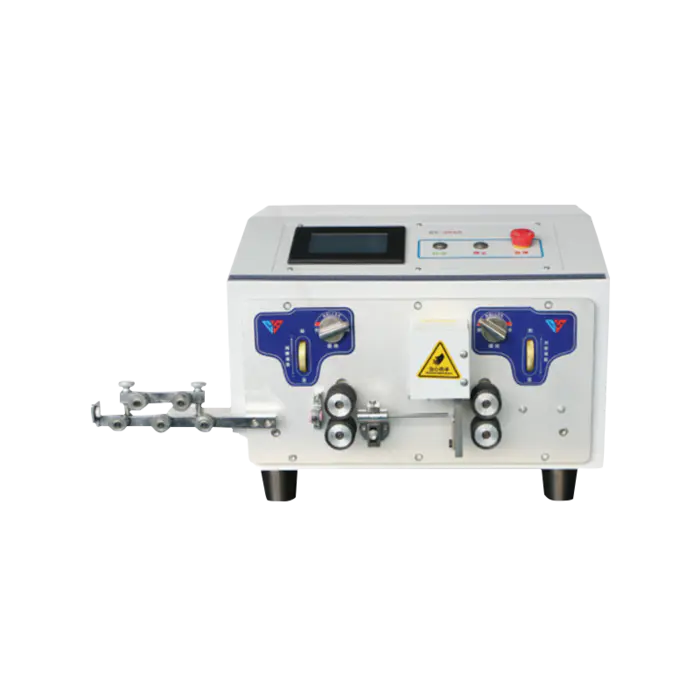

Many Automatic Stripping Machine Manufacturers have developed models with programmable features and digital interfaces. These allow operators to input parameters for various wire types, improving accuracy and repeatability. The advanced models often include sensors and microprocessors that detect irregularities, ensuring consistent output and less material waste. Manufacturers also focus on ergonomic design and easy maintenance to keep production lines running smoothly.

In addition to efficiency, the role of Automatic Stripping Machine Manufacturers extends to helping businesses optimize labor allocation. Automation reduces reliance on manual stripping and crimping, freeing skilled workers for more technical or supervisory roles. This shift not only enhances productivity but also improves workplace safety by minimizing direct contact with cutting tools.

Choosing the right Automatic Stripping Machine depends on production volume, wire specifications, and terminal requirements. Reliable Automatic Stripping Machine Manufacturers typically offer customization options to suit different applications, from small-scale workshops to large industrial plants. Their technical support and training also help companies integrate the equipment effectively into existing systems.

In a competitive manufacturing environment, investing in an Automatic Stripping Machine is not just about automation—it’s about achieving stable performance and consistent product quality. With continuous advancements from Automatic Stripping Machine Manufacturers, these systems continue to shape how modern factories handle wire processing with greater speed, precision, and confidence.