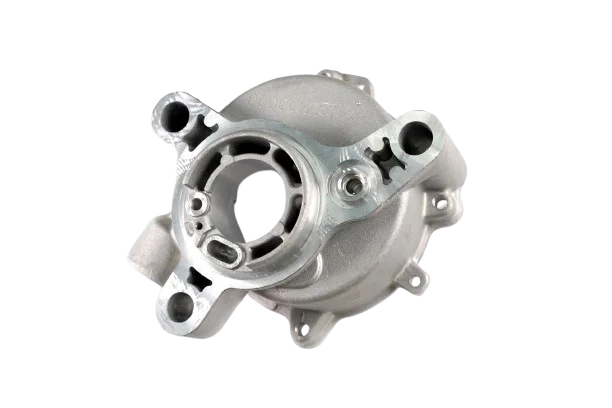

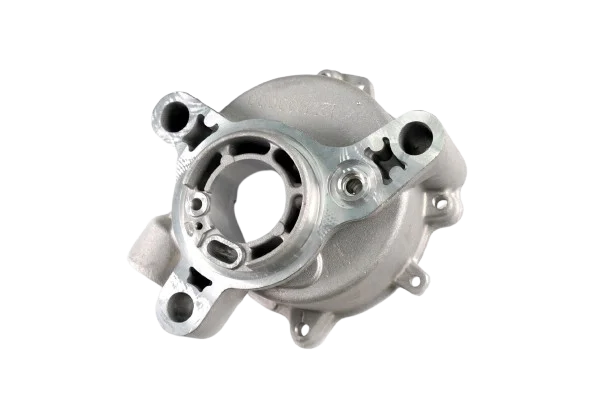

In the modern automotive industry, transmission systems play a crucial role in ensuring smooth driving performance, fuel efficiency, and long-term reliability. Among the many parts that make up these systems, the Automobile Valve Body is one of the most important components. Designed with durability and precision in mind, the Aoke's valve body shell provides both structural support and protection for internal fluid control mechanisms, allowing vehicles to perform reliably even under demanding conditions.

What Is an Automobile Valve Body?

An Automobile Valve Body is a key component used in automotive transmission and fluid control systems. It acts as the central hub that directs transmission fluid to different channels, enabling gear shifts and ensuring smooth vehicle operation. The valve body shell specifically protects internal components from harsh operating environments, such as high pressure, high temperatures, and continuous mechanical stress.

By maintaining stability and precision, the valve body ensures that a vehicle’s transmission system functions efficiently, minimizing wear and preventing failures. Without a reliable valve body, vehicles would face difficulties in gear shifting, reduced performance, and even system breakdowns.

High-Quality Material Selection

One of the defining features of a durable Automobile Valve Body is its material composition. Typically manufactured from high-strength aluminum alloy, the valve body shell offers excellent resistance to corrosion, wear, and impact. Aluminum alloys are widely favored in the automotive industry due to their lightweight yet robust properties.

Corrosion Resistance: Protects the valve body from oxidation and chemical exposure, especially when in contact with transmission fluid and other automotive chemicals.

Wear Resistance: Ensures long-lasting performance even in high-friction environments.

Impact Resistance: Provides structural stability against vibrations, shocks, and external mechanical stress.

This advanced material selection extends the lifespan of the component while ensuring that it continues to perform reliably under challenging conditions.

Precision Engineering for Reliable Performance

The Automobile Valve Body is not just about strength—it is about precision. Every channel, cavity, and passage inside the valve body must be engineered with exact measurements to ensure that transmission fluid flows correctly. Any deviation in dimensions could lead to fluid leakage, inefficient flow, or gear-shifting problems.

By using advanced manufacturing technologies such as CNC machining, heat treatment, and surface finishing, valve bodies are produced with high accuracy and minimal tolerance. This precision engineering guarantees:

Smooth Gear Shifting – Consistent fluid distribution ensures reliable gear transitions.

System Efficiency – Reduced internal friction allows for better fuel efficiency and lower heat generation.

Operational Stability – Maintains performance even under sudden acceleration, heavy loads, or extreme weather conditions.

Applications in Automotive Systems

The Automobile Valve Body is primarily used in automatic transmission systems, but its function extends across various fluid control systems in vehicles. Its applications include:

-

Automatic Transmissions – Directs hydraulic fluid to clutches and bands for gear shifting.

-

Hydraulic Control Systems – Maintains fluid pressure and flow regulation for smooth operation.

-

High-Performance Vehicles – Ensures precise transmission control for sports cars and luxury vehicles.

-

Heavy-Duty Vehicles – Provides durability and reliability under tough operating conditions such as trucks, buses, and construction machinery.

Whether in passenger cars or commercial vehicles, a high-quality valve body is critical to ensuring consistent and safe performance.

Advantages of a Durable Automobile Valve Body

Choosing a durable and precision-engineered Automobile Valve Body brings several advantages to both manufacturers and vehicle owners:

-

Enhanced Durability: Longer service life reduces replacement frequency and maintenance costs.

-

Improved Reliability: Stable operation ensures minimal breakdowns and consistent performance.

-

Better Efficiency: Optimized fluid flow reduces energy loss, leading to fuel savings.

-

Cost-Effective Investment: Although precision parts require advanced manufacturing, their longevity and reliability make them a cost-efficient choice over time.

Conclusion

The Automobile Valve Body is an essential component in automotive transmission and fluid control systems. Made from high-strength aluminum alloy and engineered with precision, it provides unmatched durability, efficiency, and stability. From passenger vehicles to heavy-duty trucks, the valve body ensures smooth gear shifting, improved reliability, and long-term cost savings.

As the automotive industry continues to evolve, the demand for high-quality, precision-engineered valve bodies will only increase. By investing in durable and reliable valve body solutions, manufacturers and vehicle owners can ensure optimal performance, safety, and efficiency on the road.