In the realm of pharmaceutical and healthcare packaging, the efficiency and accuracy of inspection machines are paramount. The BFS Light Inspection Machine is a high-precision device used to inspect various pharmaceutical packaging for foreign matter, impurities, burrs, and other quality issues. It is one of the most important quality inspection methods in modern industrial production. The inspection system can be integrated with data management systems, allowing production personnel to electronically store, review, and process all inspection data and reports at any time, ensuring the integrity and traceability of all quality information. This not only protects the interests of merchants, but also ensures that consumers in the local area have access to safe, high-quality medicines.

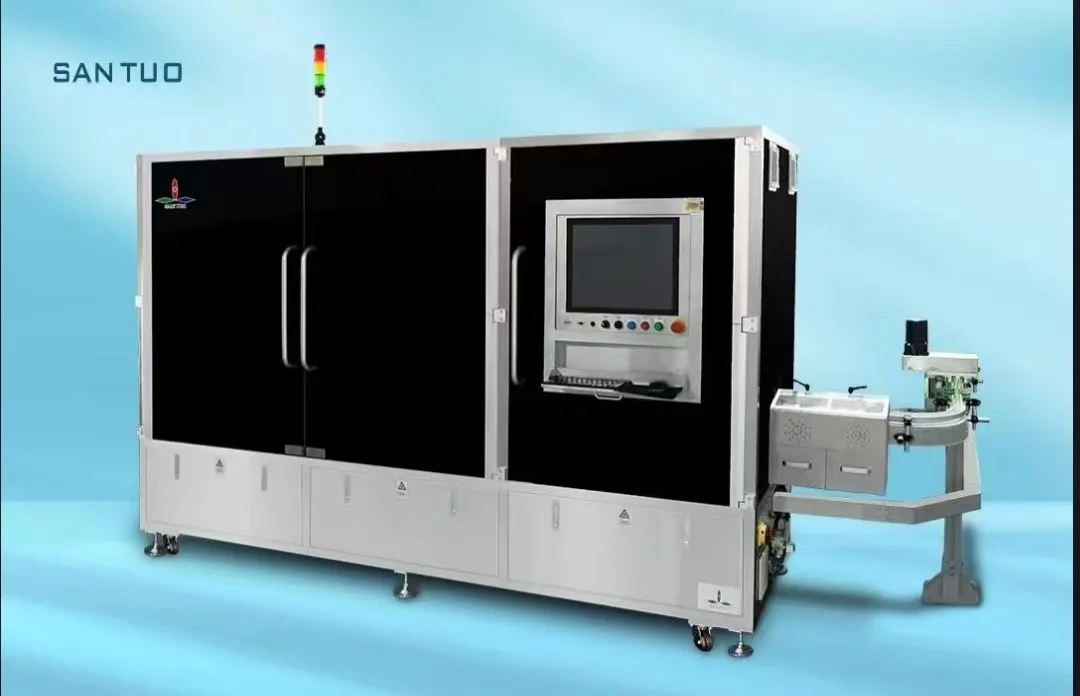

Machine Overview

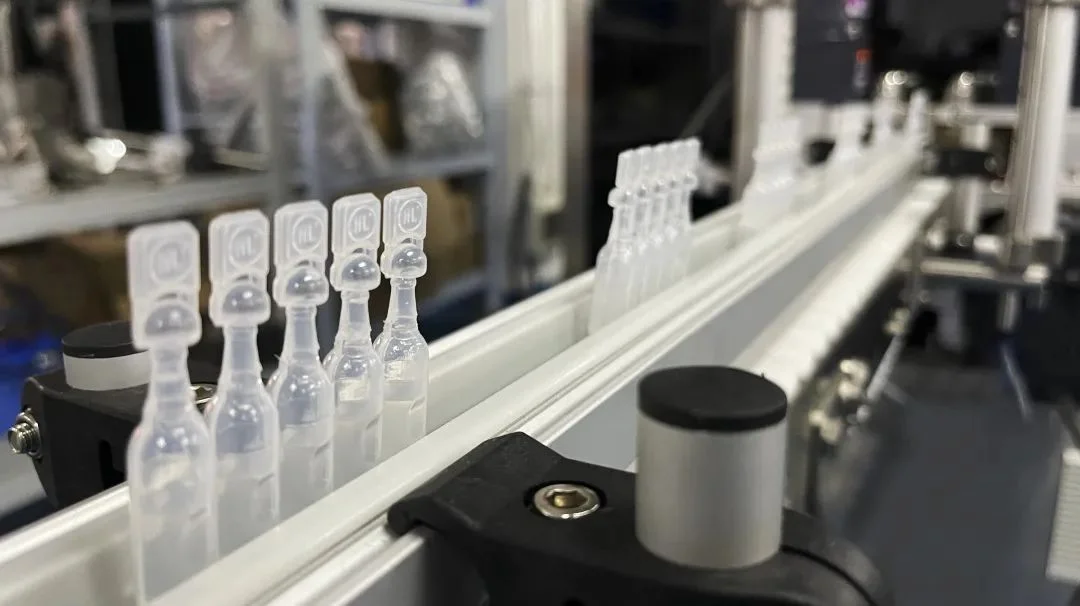

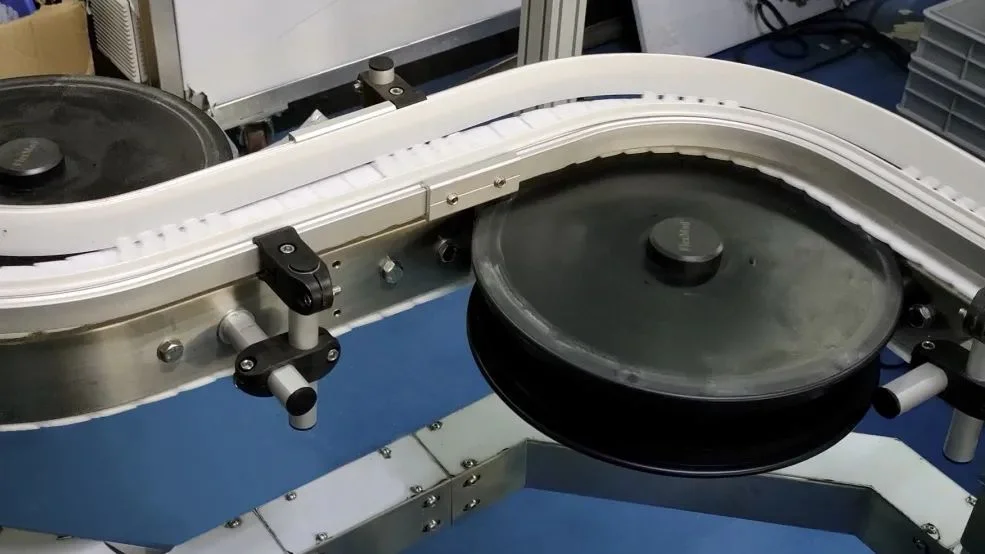

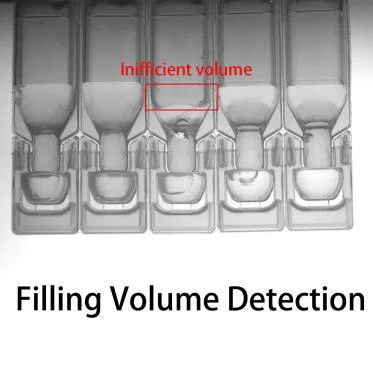

Guangzhou Santuo's BFS Light Inspection Machine is primarily used for visual inspection, liquid level detection, and internal debris detection of five- and ten-row plastic ampoules. Suitable for the pharmaceutical and daily chemical industries, the equipment utilizes an AI-powered, intelligent, high-speed imaging inspection system, offering simple operation, stable inspection, a wide range of compatible products, a low rate of missed defective product inspections, and high operational efficiency.

Voltage and Power Specifications

One of the fundamental parameters of the BFS Light Inspection Machine is its voltage and power requirements. The machine operates on a standard 220V, 50Hz power supply, which is widely available in most industrial settings. This ensures compatibility and ease of integration into existing production lines.

The Total Power consumption of the machine is 1.5kW. This energy-efficient design not only minimizes operational costs but also aligns with the growing trend towards sustainability in manufacturing. By optimizing power usage, the BFS Light Inspection Machine contributes to reducing the carbon footprint of pharmaceutical production processes.

Production Capacity and Efficiency

Efficiency is a hallmark of the BFS Light Inspection Machine. With a Rated Capacity of 150 pcs/min (five-row), this machine is capable of inspecting a significant number of containers per minute. This high throughput ensures that production lines remain operational at optimal speeds, meeting or exceeding production targets without compromising on quality.

The five-row configuration further enhances the machine's efficiency by allowing for simultaneous inspection of multiple containers. This parallel processing capability significantly reduces inspection time and increases overall productivity.

Dimensions and Footprint

When considering the integration of the BFS Light Inspection Machine into a production environment, its physical dimensions are crucial. The machine measures 2828mm in length, 900mm in width, and 2000mm in height. These dimensions provide a clear understanding of the space requirements for installation and operation.

Despite its impressive capabilities, the BFS Light Inspection Machine is designed to minimize its footprint. Its compact and ergonomic design allows for seamless integration into existing layouts without significant disruption. This space-saving feature is particularly beneficial in facilities where space is at a premium.

Inspection Capabilities and Criteria

The BFS Light Inspection Machine excels in its ability to detect a wide range of defects and irregularities. The inspection contents include:

-

Abnormal Product Appearance: Detects any deviations from the expected shape, size, or texture of the product container.

-

Abnormal Liquid Level: Identifies discrepancies in the liquid fill level within the containers.

-

Punching Burrs: Recognizes and flags any sharp edges or burrs resulting from the punching process.

-

Color Spots and Blocks: Detects unwanted color variations or patches that may indicate contamination or processing issues.

-

Punching Accumulation: Monitors for the accumulation of material around the punching area, which can affect product quality.

-

Missing Punches: Ensures that all necessary punches have been applied, preventing incomplete sealing or other defects.

The machine's precision image processing system allows for the rejection of any units that fail to meet these criteria. Importantly, the rejection accuracy can be adjusted arbitrarily, providing manufacturers with the flexibility to tailor the inspection process to their specific needs.

In conclusion, the BFS Light Inspection Machine is a powerful and versatile tool for ensuring the quality of pharmaceutical and healthcare packaging. Its key parameters, including voltage and power specifications, production capacity, and dimensions, make it an ideal choice for efficient and accurate inspection. By integrating the BFS Light Inspection Machine into their production lines, pharmaceutical manufacturers can enhance their operational efficiency, reduce defects, and ultimately deliver safer, more effective products to patients worldwide.