The welding industry has long relied on precision, consistency, and innovation. As automotive manufacturing grows more complex, the demand for advanced welding solutions has surged. In this evolving market, Dizo Automotive Welder Supplier has been steadily gaining recognition across global trade networks. Its rise is not by chance but the result of technical excellence, customer-driven design, and a strong international footprint.

Growing Importance of Automotive Welding

Welding remains a cornerstone of automotive production. From structural frames to intricate components, vehicles depend on weld integrity for both safety and performance.

Key factors driving the industry include:

-

The shift towards lightweight materials to meet emission standards.

-

Higher automation in production lines.

-

Increased demand for custom solutions to suit varied car models.

Suppliers who can adapt quickly to these demands hold a competitive advantage.

What Sets Dizo Apart in the Global Market

1. Advanced Welding Technology

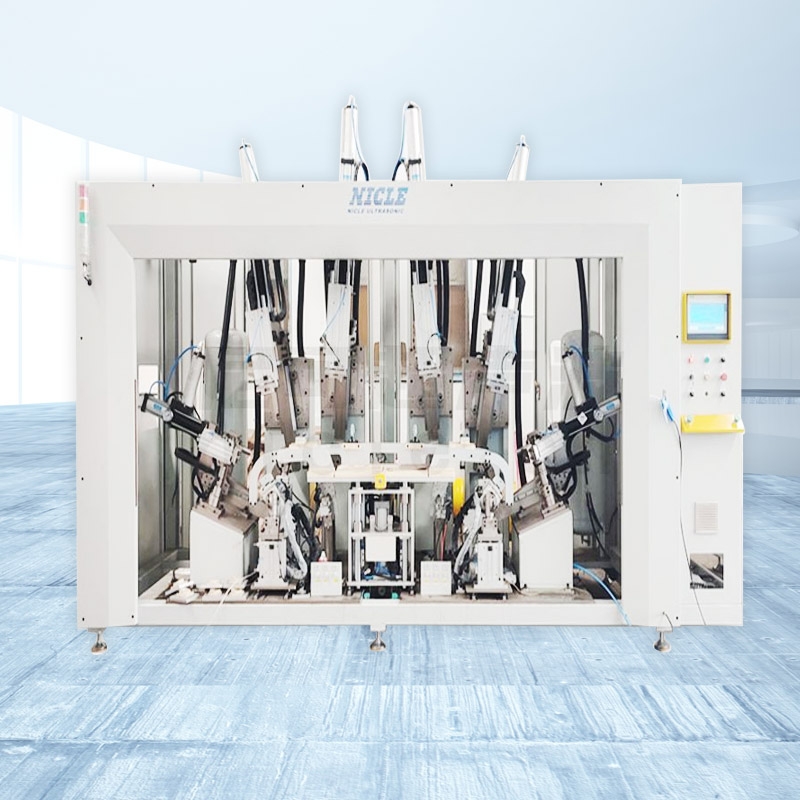

Dizo invests heavily in developing plastic welding systems that cater to modern automotive needs. Their solutions are not only compatible with traditional steel frameworks but also optimised for aluminium and composite materials. By offering high-precision, automated systems, the supplier meets the rigorous standards of today’s automotive giants.

2. Commitment to Quality

Quality is a non-negotiable factor in automotive welding. Dizo adheres to stringent international certifications and testing protocols. This dedication has earned them partnerships with some of the world’s leading automotive manufacturers. Their track record speaks to both trust and consistency—key elements in sustaining long-term contracts.

3. Global Supply and Support Network

Unlike suppliers restricted by geography, Dizo has built an expansive distribution and service framework. This global reach means that automotive manufacturers in Europe, Asia, and the Americas can access both equipment and after-sales support without delay.

Why Recognition Keeps Growing

The company’s reputation has grown not just from its products but also from its ability to respond to customer expectations. Several factors explain its rising profile:

-

Social Proof: Positive feedback from international partners has reinforced Dizo’s credibility.

-

Authority: Industry certifications and endorsements strengthen its standing.

-

Reciprocity: Clients value Dizo’s training programs and technical assistance, which give more than a simple transaction.

As the industry shifts towards electric and hybrid vehicles, welding challenges will intensify. Dizo’s readiness to tackle these new requirements positions it as a future-proof partner.

The Role of Sustainability in Welding

Global recognition also comes from a commitment to sustainability. Automotive manufacturers are under pressure to reduce carbon emissions across the supply chain. Welding suppliers must therefore focus on energy efficiency and waste reduction. Dizo has integrated eco-conscious practices, from energy-efficient equipment to recyclable consumables. This alignment with global priorities adds another layer of trust.

Looking Ahead: Innovation in Electric Vehicles

The transition to electric vehicles (EVs) has created a new set of welding requirements. Battery packs, lightweight chassis, and high-strength alloys need welding precision beyond traditional methods. Dizo has adapted by developing:

-

Spot welding systems for battery casing.

-

Robotic solutions for complex assembly lines.

-

Intelligent monitoring to track weld quality in real time.

These innovations are a direct response to where the automotive sector is heading, ensuring Dizo remains relevant on the global stage.

Final Thoughts

Global recognition in the welding industry is not easily won. It requires consistent delivery of quality, adaptability to market shifts, and long-term trust with clients. Dizo Automotive Welder Supplier has achieved this by aligning technical expertise with customer needs and global standards.