In the automotive industry, electrical systems play a crucial role in ensuring the smooth functioning of a vehicle. From the engine to the infotainment system, and everything in between, electrical wiring is responsible for connecting various components, enabling them to communicate and work together seamlessly. Among the essential components in automotive electrical systems are wiring harnesses—complex assemblies of wires, connectors, and terminals that transport electrical signals and power throughout a vehicle.

In this comprehensive guide, we will explore the importance of quality in automotive wiring harnesses, highlighting how high-quality components contribute to vehicle performance, safety, and durability. Additionally, we will discuss how companies like Xinying, a leading manufacturer of electronic wires, terminal wire harnesses, connector harnesses, and high-temperature wire harnesses, are setting the standard for excellence in the industry.

What is an Automotive Wiring Harness?

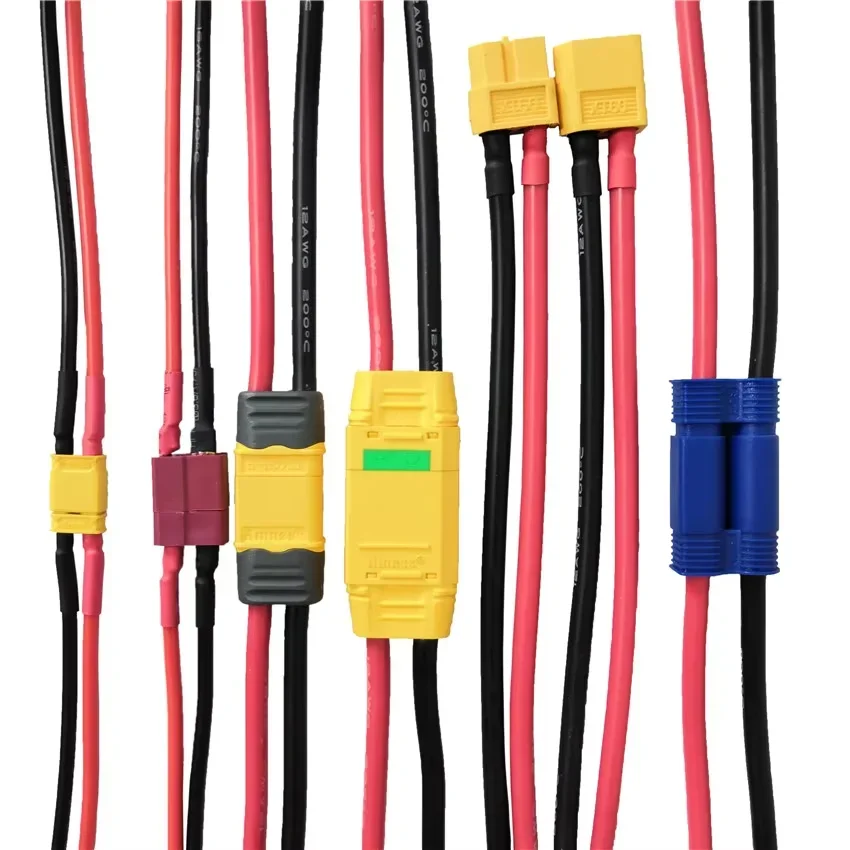

An automotive wiring harness is essentially a bundle of wires organized and protected by insulation, connectors, and terminals. These harnesses serve as the electrical pathways that connect various electrical and electronic components in a vehicle, such as lights, sensors, power windows, airbags, and the engine control unit (ECU). A well-designed wiring harness ensures that electrical signals and power flow efficiently and safely across the vehicle’s electrical system.

The quality of the wiring harness is vital because it directly impacts the vehicle’s overall performance, safety, and longevity. In fact, faulty or poorly constructed wiring harnesses can lead to electrical failures, malfunctions, or even dangerous situations on the road.

Why Quality in Automotive Wiring Harnesses Matters

1. Ensuring Electrical Safety

Electrical safety is paramount in any automotive system, and wiring harnesses play a critical role in protecting both the vehicle’s electronics and its occupants. Poor-quality wiring harnesses with inadequate insulation or connectors can lead to short circuits, overheating, or even fires. These issues can be devastating, both for the vehicle’s electronics and, more importantly, for the safety of the passengers.

Xinying, as a specialist in manufacturing high-quality wiring harnesses, uses advanced insulation materials and ensures that the connectors are made to withstand harsh automotive environments. This attention to detail significantly reduces the risk of electrical failures, contributing to both vehicle safety and compliance with international safety standards.

2. Enhancing Vehicle Reliability

The reliability of an automotive wiring harness is directly tied to the overall performance of the vehicle. Wiring harnesses that are poorly constructed or use subpar materials can suffer from issues such as fraying, corrosion, or loose connections. These problems can lead to intermittent failures or complete electrical malfunctions, affecting vital systems such as the brakes, airbags, and steering.

When manufacturers like Xinying produce wiring harnesses, they prioritize high-quality materials such as high-temperature-resistant wires and durable connectors. These materials ensure that the wiring harnesses maintain their integrity and reliability, even under extreme conditions such as high temperatures, vibration, and moisture exposure. This contributes to the vehicle’s longevity and reduces the likelihood of expensive repairs or breakdowns.

3. Improving Performance and Efficiency

Automotive wiring harnesses are designed to deliver precise electrical signals and power to various components in a vehicle. Whether it's the timing of the engine's ignition system or the operation of sensors for fuel efficiency, the quality of the wiring harnesses affects the vehicle’s overall performance. Low-quality wiring harnesses can cause poor connectivity, resulting in power loss, erratic behavior of electrical components, and compromised fuel efficiency.

By investing in high-quality wiring harnesses from manufacturers like Xinying, which specialize in precision engineering and high-performance materials, automotive manufacturers ensure that their vehicles run smoothly. The improved performance leads to better fuel economy, enhanced driving experience, and optimized power delivery to essential vehicle systems.

4. Meeting Stringent Industry Standards

Automotive wiring harnesses are subject to strict regulatory standards due to the high risks associated with electrical failures. For example, wiring harnesses need to pass tests for thermal endurance, vibration resistance, and flame retardancy to ensure they can withstand the challenging conditions inside a vehicle.

Xinying adheres to international standards such as ISO 9001, IATF 16949, and UL certification to guarantee that their wiring harnesses meet or exceed the required quality specifications. This level of certification ensures that the products are manufactured to withstand extreme environments, guaranteeing the highest standards of safety, performance, and durability.

5. Facilitating Customization and Adaptability

The automotive industry is highly competitive, and manufacturers are constantly seeking ways to differentiate their vehicles with innovative features and cutting-edge technology. Automotive wiring harnesses must be adaptable to accommodate new technologies such as electric drivetrains, advanced driver-assistance systems (ADAS), infotainment systems, and more.

Xinying, with its deep expertise in producing custom wiring solutions, offers a wide range of options, from terminal wire harnesses to connector harnesses and high-temperature wire harnesses. These options allow automotive manufacturers to tailor their wiring harnesses to suit the specific requirements of their vehicles, making it easier to integrate new technologies while maintaining the highest quality and performance standards.

The Role of Xinying in Advancing Automotive Wiring Harness Quality

As a professional manufacturer specializing in electronic wire, terminal wire harnesses, connector harnesses, and high-temperature wire harnesses, Xinying plays a key role in providing high-quality solutions to the automotive industry. Their commitment to quality and innovation has earned them a reputation as a trusted supplier for leading automotive manufacturers.

Xinying's expertise in producing wiring harnesses that meet international standards for durability, safety, and performance ensures that automotive manufacturers can rely on their products to keep up with the ever-evolving demands of the industry. With their advanced production capabilities and state-of-the-art testing procedures, Xinying delivers reliable and high-performance wiring solutions that contribute to the success of modern vehicles.

Conclusion

The importance of quality in automotive wiring harnesses cannot be overstated. These components are the lifeblood of the vehicle’s electrical system, ensuring everything from safety to performance runs smoothly. High-quality wiring harnesses contribute to electrical safety, vehicle reliability, enhanced performance, and compliance with industry standards, all while supporting the development of new automotive technologies.

Manufacturers like Xinying, with their commitment to precision, durability, and innovation, are setting the bar for quality in the automotive wiring harness industry. By prioritizing top-tier materials and advanced manufacturing techniques, they help ensure that automotive wiring harnesses meet the rigorous demands of the automotive industry, contributing to safer, more efficient, and longer-lasting vehicles on the road.

Troubleshooting Solutions for Common Problems in Automotive Wiring Harness Systems