In the world of electrical engineering, the role of electric motors cannot be overstated. They power everything from household appliances and industrial machines to advanced robotics and electric vehicles. At the heart of any electric motor lies the stator—a fundamental component that ensures the motor operates efficiently, reliably, and with long-lasting performance. Understanding the importance of motor stators is essential for engineers, manufacturers, and anyone involved in the design or maintenance of electrical systems.

In this article, we’ll dive deep into the significance of motor stators, their role in electrical engineering, and how Longnai, a leading company specializing in motor sample development and manufacturing, contributes to advancing this crucial technology.

What is a Motor Stator?

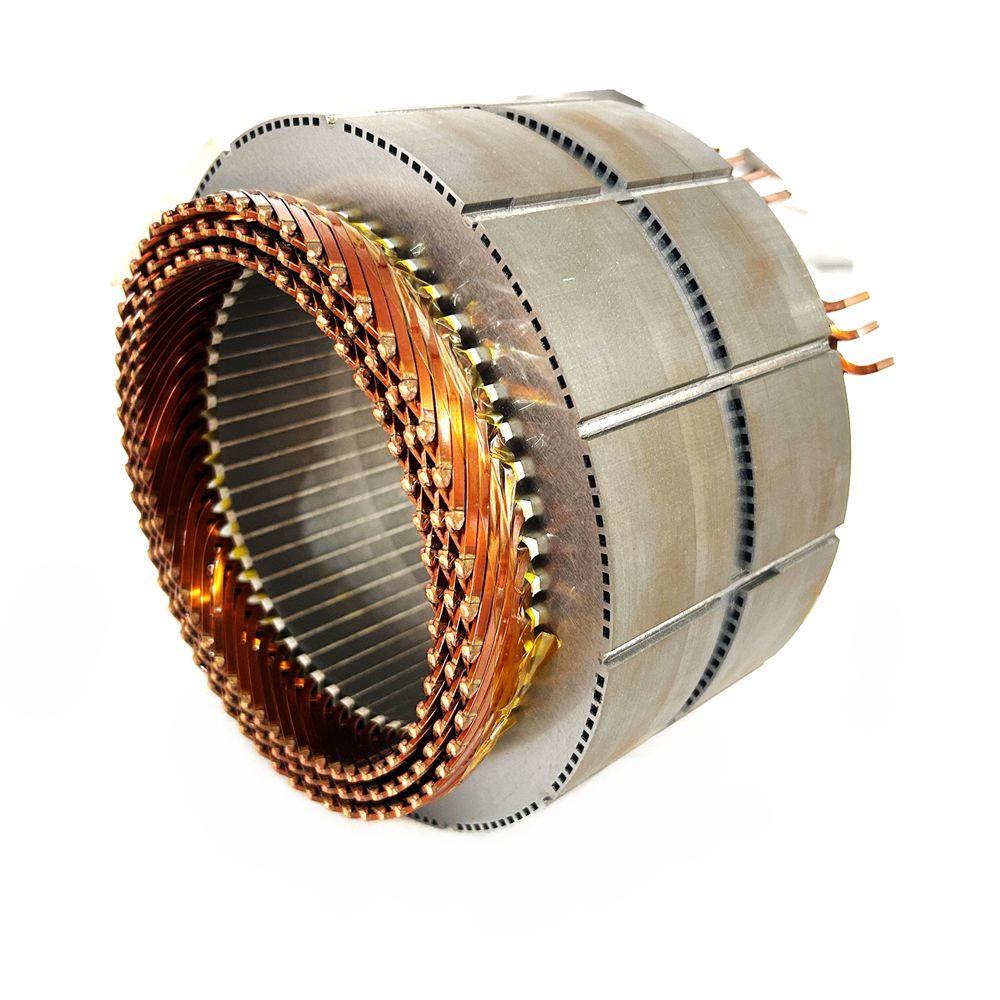

The stator is the stationary part of an electric motor. It consists of coils of wire, typically copper, wrapped around an iron core. The stator works together with the rotor (the rotating part of the motor) to create the magnetic field necessary for motor operation. When electric current flows through the stator coils, it generates a magnetic field that interacts with the rotor, causing it to rotate and produce mechanical energy.

While the rotor does the physical work by converting electrical energy into motion, the stator is responsible for generating the magnetic field and providing the foundational energy to drive the motor. Thus, a properly designed and high-quality stator is critical for ensuring the motor's overall performance.

Why are Motor Stators So Important?

Efficient Energy Conversion

The efficiency of an electric motor hinges on the quality of its stator. A high-quality stator ensures that electrical energy is efficiently converted into mechanical energy with minimal losses. This is especially crucial in industries where energy consumption is a primary concern, such as manufacturing, electric vehicles, and renewable energy systems. An efficient stator not only helps reduce energy costs but also minimizes environmental impact by conserving power.

Motor Stability and Reliability

Stators are the foundation for motor stability. The consistency and performance of the stator directly influence the motor’s operational stability. A well-constructed stator ensures that the motor operates smoothly, avoiding irregularities like overheating, excessive vibration, or malfunctioning. In high-precision applications, such as robotics or medical equipment, motor stability is essential for achieving reliable and accurate results. Poor-quality stators can lead to motor failure, downtime, and costly repairs, which can disrupt operations.

Durability and Lifespan

The longevity of an electric motor is determined, in large part, by the quality of its stator. Inferior stators can lead to overheating, degradation of materials, and eventual motor failure. A high-quality stator, designed with durable materials and precise manufacturing, ensures the motor performs optimally for many years. This is particularly important in industries like automotive and aerospace, where reliability and long-term performance are critical.

Thermal Management

Motors generate heat during operation, and the stator plays an important role in managing this heat. High-quality stators are designed with materials that help dissipate heat effectively, ensuring the motor does not overheat. Overheating can lead to insulation breakdown, reduced efficiency, and even permanent damage to the motor. A stator with good thermal management properties ensures the motor operates within its safe temperature range, enhancing both its performance and longevity.

Reducing Noise and Vibration

Excessive noise and vibration in motors can be a significant issue, especially in sensitive environments like medical devices or consumer electronics. A high-quality stator helps minimize unwanted vibrations and noise during operation, creating a smoother and more stable motor. This not only improves the user experience but also reduces wear and tear on other motor components.

How Longnai Contributes to the Advancement of Motor Stators

Longnai is a company that specializes in the research, development, and manufacturing of motor stators and related components. With years of expertise in the industry, Longnai plays a vital role in producing motor stators that meet the high standards of electrical engineering.

Innovation in Motor Stator Design

Longnai’s commitment to innovation has allowed them to stay at the forefront of motor stator technology. Their R&D team is constantly exploring new materials, designs, and manufacturing techniques to improve the efficiency, performance, and durability of motor stators. This focus on innovation helps meet the evolving needs of industries like electric vehicles, renewable energy, robotics, and industrial automation.

Customization for Diverse Applications

No two motor applications are the same. Whether it’s a high-speed motor for a power tool or a low-noise motor for a consumer appliance, the stator must be tailored to the specific needs of the application. Longnai excels in customizing motor stators for a wide variety of industries. By working closely with clients to understand their requirements, Longnai designs and manufactures stators that are optimized for specific performance criteria, such as size, power output, efficiency, and environmental conditions.

Quality Manufacturing and Precision Engineering

At Longnai, quality is a top priority. Using state-of-the-art equipment and strict quality control measures, the company ensures that every stator is manufactured to the highest standards. Each stator undergoes rigorous testing to verify its performance, durability, and efficiency before it’s delivered to clients. This dedication to precision manufacturing guarantees that Longnai’s stators contribute to the overall reliability and longevity of the motors in which they are used.

Sustainability and Environmental Responsibility

As industries shift towards more sustainable solutions, Longnai is committed to producing motor stators that align with environmental goals. The company uses eco-friendly materials and energy-efficient manufacturing processes to reduce waste and lower carbon footprints. By providing high-performance stators that minimize energy consumption and extend motor lifespan, Longnai is playing a key role in advancing environmentally responsible technology.

The Future of Motor Stators in Electrical Engineering

As electrical engineering continues to evolve, so too will the demands placed on motor stators. With the rise of electric vehicles, automation, and renewable energy solutions, the need for high-quality, efficient, and durable motor components is expected to grow. Innovations in materials, thermal management, and design will be critical in meeting these future demands.

Companies like Longnai, with their expertise in motor stator research and development, are well-positioned to lead the way in this exciting era of technological progress. As industries strive for greater efficiency, reliability, and sustainability, motor stators will remain a cornerstone of modern electrical engineering.

Conclusion

Motor stators may not always be in the spotlight, but they are undeniably critical to the functionality of electric motors. Their role in ensuring energy efficiency, stability, and durability is essential to the performance of machines across countless industries. With companies like Longnai at the forefront of motor stator research and manufacturing, the future of electric motor technology looks bright, efficient, and sustainable.

Understanding the importance of motor stators not only helps engineers design better systems but also empowers manufacturers to produce machinery that meets the demands of tomorrow’s technology.

Customizing New Energy Motor Stator Assemblies: Tailoring Solutions for Diverse Applications