In the pharmaceutical industry, maintaining stringent quality control measures is paramount to ensure the safety and efficacy of medications. Gasketed plate heat exchangers K150B play a crucial role in pharmaceutical manufacturing processes, facilitating precise temperature control and efficient heat transfer. This blog explores the importance of quality control in pharmaceuticals, focusing on the role of gasketed plate heat exchangers in ensuring product quality and compliance with regulatory standards.

Importance of Quality Control in Pharmaceuticals

Quality control is a fundamental aspect of pharmaceutical manufacturing, encompassing various processes and procedures designed to guarantee the consistency, purity, and safety of pharmaceutical products. In the pharmaceutical industry, even minor deviations in manufacturing conditions can have significant implications for product quality and patient safety. Quality control measures are implemented to detect and prevent such deviations, ensuring that pharmaceutical products meet regulatory requirements and performance standards.

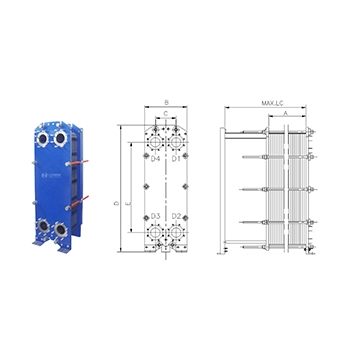

The Role of Gasketed Plate Heat Exchangers K150B in Quality Control

https://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-K150B.shtml K150B are widely used in pharmaceutical manufacturing for their ability to provide precise temperature control, rapid heat transfer, and hygienic processing. These heat exchangers play a critical role in maintaining the integrity of pharmaceutical products by ensuring that they are processed under controlled and optimal conditions. Here are some key aspects of how gasketed plate heat exchangers contribute to quality control in pharmaceuticals:

1. Temperature Control:

Maintaining precise temperature control is essential in pharmaceutical manufacturing to ensure the stability and efficacy of medications. Gasketed plate heat exchangers K150B allow for accurate temperature regulation during processes such as heating, cooling, and sterilization, minimizing the risk of thermal degradation and preserving product quality.

2. Efficiency and Productivity:

Gasketed plate heat exchangers K150B are known for their high heat transfer efficiency, which enables rapid and uniform heating or cooling of pharmaceutical products. This efficiency not only improves production throughput but also helps maintain consistent product quality by minimizing processing variations.

3. Cleanability and Hygiene:

Hygiene is a critical consideration in pharmaceutical manufacturing to prevent contamination and ensure product safety. Gasketed plate heat exchangers K150B are designed for easy cleaning and sanitation, with smooth surfaces and removable plates that facilitate thorough cleaning procedures. This cleanliness feature is essential for maintaining high standards of hygiene and quality control in pharmaceutical production.

Best Practices for Quality Control with Gasketed Plate Heat Exchangers K150B

1. Regular Maintenance and Calibration:

To ensure consistent performance and accuracy, gasketed plate heat exchangers K150B should undergo regular maintenance and calibration checks. Routine inspections, cleaning, and servicing of the heat exchanger components are essential to prevent malfunctions and maintain quality control standards.

2. Monitoring and Documentation:

Implementing a robust monitoring system to track key parameters such as temperature, pressure, and flow rates is crucial for quality control in pharmaceutical manufacturing. Keep detailed records of process parameters, maintenance activities, and any deviations from set standards to facilitate compliance with regulatory requirements.

3. Staff Training and Compliance:

Proper training of personnel involved in operating and maintaining gasketed plate heat exchangers K150B is essential for ensuring quality control in pharmaceutical production. Employees should be well-versed in the equipment's operation, maintenance procedures, and safety protocols to minimize errors and uphold quality standards.

Conclusion

Quality control is a cornerstone of pharmaceutical manufacturing, and gasketed plate heat exchangers K150B play a vital role in maintaining product quality, safety, and compliance with regulatory standards. By incorporating best practices for quality control and leveraging the efficiency and reliability of gasketed plate heat exchangers K150B, pharmaceutical companies can uphold the highest standards of quality in their manufacturing processes.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.

Welcome to work with YOJO, we will provide the gasketed plate heat exchangers K150B solution for your specific needs.

E-mail:zy@jsyuanzhuo.com