Brazed plate heat exchangers have revolutionized the way heat transfer is handled in various industries, offering a compact, efficient, and cost-effective solution for heating and cooling applications. Among the wide range of brazed plate heat exchangers available in the market, Model ZL200A stands out as a top-performing and energy-saving option. In this blog, we will delve into the features, benefits, and applications of https://www.yojointernational.com/Brazed-Plate-Heat-Exchanger/Brazed-Plate-Heat-Exchanger-ZL200A.shtml and explore how it serves as an efficient heat exchange solution.

Overview of Brazed Plate Heat Exchanger Model ZL200A

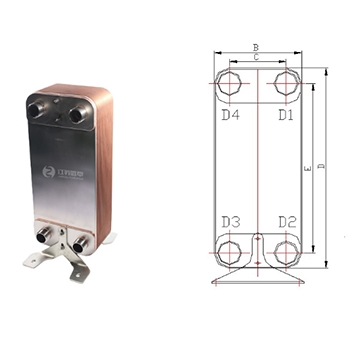

Brazed Plate Heat Exchanger Model ZL200A is a high-quality, compact heat exchanger designed for optimal heat transfer efficiency and energy savings. This model features a series of stainless steel plates that are brazed together to form efficient heat exchange channels. The ZL200A is known for its exceptional performance, reliability, and versatility, making it a popular choice for a wide range of heating and cooling applications.

Key Features of Brazed Plate Heat Exchanger Model ZL200A

1. Compact Design: The ZL200A brazed plate heat exchanger is compact in size, making it ideal for installations where space is limited. Its small footprint allows for easy integration into existing systems without the need for extensive modifications, saving both space and installation costs.

2. High Thermal Efficiency: Model ZL200A is designed for optimal heat transfer efficiency, with a corrugated plate design that promotes turbulent flow and enhances heat transfer rates. This results in faster heating or cooling of fluids, leading to energy savings and improved system performance.

3. Durable Construction: The ZL200A is constructed from high-quality stainless steel plates that are brazed together using advanced technology, ensuring durability and long-term performance. The robust construction of this heat exchanger makes it suitable for demanding industrial applications.

4. Wide Operating Temperature Range: Brazed Plate Heat Exchanger Model ZL200A is capable of handling a wide range of operating temperatures, making it suitable for both high-temperature and low-temperature applications. This versatility allows for flexible use in various heating and cooling systems.

5. Easy Maintenance: The ZL200A is designed for easy maintenance and cleaning, with a simple plate design that allows for quick access to internal components. Routine maintenance of this heat exchanger is straightforward, reducing downtime and ensuring continuous operation.

Benefits of Brazed Plate Heat Exchanger Model ZL200A

1. Energy Efficiency: The high thermal efficiency of Brazed Plate Heat Exchanger Model ZL200A results in significant energy savings for heating and cooling systems. By minimizing heat loss and maximizing heat transfer rates, the ZL200A helps reduce energy consumption and operating costs.

2. Cost-Effectiveness: The compact design, durable construction, and long service life of the ZL200A make it a cost-effective heat exchange solution. The initial investment in this heat exchanger is quickly offset by energy savings and reduced maintenance costs over time.

3. Versatility: Model ZL200A is a versatile heat exchanger that can be used in a wide range of applications, including HVAC systems, refrigeration, industrial processing, and renewable energy systems. Its ability to handle different fluids and operating conditions makes it a flexible solution for diverse heating and cooling requirements.

4. Improved System Performance: By enhancing heat transfer efficiency and promoting faster heating and cooling of fluids, the ZL200A contributes to improved system performance and overall productivity. This results in better temperature control, reduced processing times, and enhanced operational efficiency.

Applications of Brazed Plate Heat Exchanger Model ZL200A

1. HVAC Systems: Brazed Plate Heat Exchanger Model ZL200A is commonly used in heating, ventilation, and air conditioning (HVAC) systems to transfer heat between air and water or refrigerant fluids. Its compact size, high thermal efficiency, and reliable performance make it an ideal choice for HVAC applications in residential, commercial, and industrial settings.

2. Refrigeration: The ZL200A is also well-suited for refrigeration applications, where it is used to cool or freeze products in food processing, cold storage, and transportation industries. Its rapid heat transfer capabilities and versatile operating temperature range make it an effective solution for maintaining product quality and safety.

3. Industrial Processing: In industrial applications such as chemical manufacturing, pharmaceutical production, and wastewater treatment, Model ZL200A plays a crucial role in heating, cooling, and temperature control processes. Its durable construction, high thermal efficiency, and wide operating temperature range make it a reliable choice for demanding industrial environments.

4. Renewable Energy Systems: Brazed Plate Heat Exchanger Model ZL200A is an integral component of renewable energy systems such as solar thermal collectors, geothermal heat pumps, and biomass boilers. By efficiently transferring heat between renewable energy sources and fluid loops, the ZL200A helps maximize energy output and system performance in sustainable energy applications.

Conclusion

Brazed Plate Heat Exchanger Model ZL200A is a top-performing and energy-saving solution for heating and cooling applications in various industries. With its compact design, high thermal efficiency, durable construction, and versatile operating temperature range, the ZL200A offers numerous benefits for HVAC systems, refrigeration, industrial processing, and renewable energy systems. By leveraging the features and advantages of Model ZL200A, businesses and organizations can optimize their heat exchange processes, reduce energy consumption, and enhance overall system performance. As the demand for energy-efficient and cost-effective solutions continues to grow, Brazed Plate Heat Exchanger Model ZL200A is poised to play a crucial role in meeting the heating and cooling needs of diverse industries.

Exploring the Applications of BPHE Model ZL200A in Industrial Processes