When it comes to heat exchange systems, efficiency and cost-effectiveness are key factors to consider. Gasketed plate heat exchangers have emerged as a popular choice for many industries due to their ability to provide efficient heat transfer at a lower cost compared to other traditional heat exchange options. In this blog post, we will delve into the world of gasketed plate heat exchangers, exploring their benefits, working principles, and why they are considered a cost-effective heat exchange option.

Introduction to Gasketed Plate Heat Exchangers

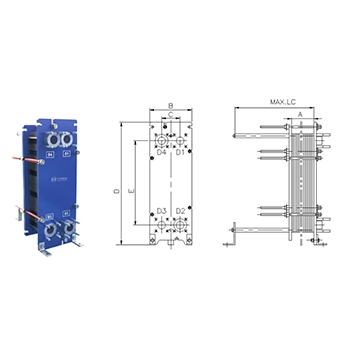

https://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-B30B.shtml are compact heat exchange systems that consist of multiple plates arranged in a frame. These plates are sealed with gaskets to prevent leakage and create flow channels for the transfer of heat between two fluids. The design of gasketed plate heat exchangers allows for a large surface area for heat transfer in a relatively small footprint, making them highly efficient and space-saving compared to other types of heat exchangers.

Benefits of Gasketed Plate Heat Exchangers

Cost-Effective Solution: One of the primary advantages of gasketed plate heat exchangers is their cost-effectiveness. The compact design and high heat transfer efficiency of these systems result in lower installation and operating costs compared to traditional shell-and-tube heat exchangers. Additionally, gasketed plate heat exchangers require less maintenance and downtime, further reducing overall costs for businesses.

High Heat Transfer Efficiency: Gasketed plate heat exchangers offer superior heat transfer efficiency due to their large surface area and turbulent flow design. This allows for quick and effective heat exchange between fluids, resulting in optimal temperature control and energy savings. The efficiency of gasketed plate heat exchangers makes them ideal for a wide range of applications, including HVAC systems, food processing, and industrial cooling processes.

Working Principles of Gasketed Plate Heat Exchangers

Gasketed plate heat exchangers operate on the principle of counterflow heat exchange, where two fluids flow in opposite directions within the heat exchanger. As the hot fluid passes through one set of plates, it transfers heat to the cold fluid flowing through another set of plates. The gaskets between the plates ensure that the fluids remain separate and prevent any leakage during the heat exchange process. The turbulent flow created by the plates enhances heat transfer efficiency, allowing for rapid temperature adjustment between the two fluids.

Applications of Gasketed Plate Heat Exchangers

Gasketed plate heat exchangers are widely used in various industries for a range of applications, including:

HVAC Systems: Gasketed plate heat exchangers are commonly used in HVAC systems for heating, ventilation, and air conditioning. These systems help regulate temperature and humidity levels in buildings, providing a comfortable indoor environment while minimizing energy consumption.

Food Processing: In the food industry, gasketed plate heat exchangers are used for pasteurization, sterilization, and cooling processes. These systems ensure the safety and quality of food products by efficiently controlling temperature during production.

Industrial Cooling: Gasketed plate heat exchangers are also utilized in industrial cooling processes, such as refrigeration and air conditioning units. The high heat transfer efficiency of these systems allows for effective cooling of industrial equipment and machinery, reducing the risk of overheating and equipment failure.

Conclusion

Gasketed plate heat exchangers offer a cost-effective and efficient solution for heat exchange in various industries. Their compact design, high heat transfer efficiency, and easy maintenance make them a popular choice for businesses looking to optimize their heating and cooling processes. By investing in a gasketed plate heat exchanger, businesses can achieve significant cost savings, improved energy efficiency, and reliable temperature control for their operations. Experience the benefits of gasketed plate heat exchangers and elevate your heat exchange capabilities today.

Gasketed Plate Heat Exchanger B30B: The Best Choice for Energy-Saving Heat Exchange