In today's energy-conscious world, finding efficient and sustainable solutions for heat exchange is crucial. One such solution that has gained significant popularity is thehttps://www.yojointernational.com/Gasketed-Plate-Heat-Exchanger/Gasketed-Plate-Heat-Exchanger-B30B.shtml. This innovative technology offers numerous advantages over traditional heat exchangers, making it the best choice for energy-saving heat exchange applications. In this article, we will explore the features, benefits, and applications of the gasketed plate heat exchanger B30B, highlighting why it is the preferred option for industries worldwide.

I. Understanding the Gasketed Plate Heat Exchanger B30B

A. Working Principle

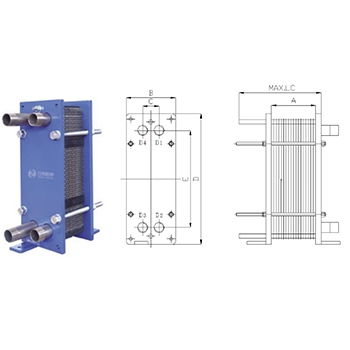

The gasketed plate heat exchanger B30B is a compact and efficient device used for transferring heat between two fluids. It consists of a series of corrugated plates with gaskets, which are compressed together to form alternating channels for the hot and cold fluids. The heat transfer occurs through the plates, allowing the fluids to exchange heat without mixing.

B. Key Components and Design Features

The B30B heat exchanger is designed with several key components to ensure optimal performance. These include the plates, gaskets, frame, and connections. The plates are made of stainless steel or other suitable materials, providing excellent heat transfer properties. The gaskets, typically made of elastomers, create a seal between the plates, preventing any leakage between the hot and cold fluids. The frame holds the plates together and provides support, while the connections allow for the inlet and outlet of the fluids.

C. How the B30B Differs from Other Heat Exchanger Types

Compared to other heat exchanger types, such as shell and tube or tube-in-tube, the gasketed plate heat exchanger B30B offers several distinct advantages. Firstly, its compact design allows for a higher heat transfer surface area within a smaller footprint, making it ideal for applications with limited space. Additionally, the B30B's plate design promotes turbulent flow, enhancing heat transfer efficiency. The gaskets also provide flexibility, allowing for easy maintenance and replacement if needed.

II. Advantages of Gasketed Plate Heat Exchanger B30B

A. High Thermal Efficiency and Heat Transfer Performance

The B30B heat exchanger offers exceptional thermal efficiency due to its large heat transfer surface area and turbulent flow characteristics. The corrugated plates create turbulence in the fluid flow, maximizing heat transfer rates. This results in improved energy efficiency and reduced operating costs.

B. Compact Design and Space-Saving Benefits

The compact design of the B30B heat exchanger allows for efficient use of space. Compared to traditional heat exchangers, it requires significantly less floor area, making it suitable for installations where space is limited. The compact size also reduces the amount of piping required, further optimizing space utilization.

C. Versatility and Flexibility in Applications

The gasketed plate heat exchanger B30B is highly versatile and can be used in a wide range of applications. It is suitable for both liquid-to-liquid and liquid-to-gas heat exchange processes. The ability to handle different fluid types, temperatures, and pressures makes it adaptable to various industries, including HVAC systems, industrial processes, power generation, food and beverage, and chemical manufacturing.

D. Easy Maintenance and Cleaning Procedures

Maintaining and cleaning the B30B heat exchanger is relatively simple. The gaskets can be easily replaced if damaged or worn out, ensuring a tight seal between the plates. Routine maintenance involves inspecting the plates for fouling or scaling and cleaning them if necessary. The accessibility of the plates simplifies the cleaning process, reducing downtime and maintenance costs.

III. Energy-Saving Features of Gasketed Plate Heat Exchanger B30B

A. Reduced Energy Consumption and Operating Costs

The high thermal efficiency of the B30B heat exchanger translates into reduced energy consumption. By maximizing heat transfer rates, it minimizes the temperature difference required between the hot and cold fluids, resulting in energy savings. Lower energy consumption leads to reduced operating costs, making the B30B an economically viable choice for heat exchange applications.

B. Optimized Heat Recovery and Waste Heat Utilization

The B30B heat exchanger is particularly effective in heat recovery applications. It can recover and utilize waste heat from various processes, such as exhaust gases or hot water streams, to preheat incoming fluids. This not only reduces energy consumption but also minimizes the environmental impact by utilizing otherwise wasted heat.

C. Enhanced System Performance and Overall Efficiency

Integrating the B30B heat exchanger into a system improves its overall performance and efficiency. By efficiently transferring heat between fluids, it helps maintain optimal operating conditions, reducing the load on other equipment such as boilers or chillers. This leads to improved system efficiency and longevity, further contributing to energy savings.

IV. Applications of Gasketed Plate Heat Exchanger B30B

A. HVAC Systems and Building Services

The B30B heat exchanger is widely used in HVAC systems for heating, ventilation, and air conditioning. It efficiently transfers heat between the hot and cold water loops, ensuring comfortable indoor temperatures while minimizing energy consumption. It is also utilized in building services, such as district heating and cooling networks, to optimize energy efficiency.

B. Industrial Processes and Manufacturing

In industrial processes, the B30B heat exchanger plays a crucial role in various applications. It is used for heat recovery, process cooling, and heating in industries such as chemical manufacturing, pharmaceuticals, pulp and paper, and metal processing. Its versatility and efficiency make it an essential component in optimizing energy usage and reducing operating costs.

C. Power Generation and Renewable Energy

The B30B heat exchanger is employed in power plants for heat recovery from flue gases, steam condensation, and cooling of turbine lubrication systems. It helps improve the overall efficiency of power generation processes, reducing fuel consumption and emissions. Additionally, it finds applications in renewable energy systems, such as geothermal and solar thermal, for efficient heat transfer.

D. Food and Beverage Industry

In the food and beverage industry, the B30B heat exchanger is utilized for pasteurization, sterilization, and cooling processes. It ensures precise temperature control and minimizes thermal degradation of sensitive food products. The compact design and ease of cleaning make it suitable for hygienic applications, meeting stringent industry standards.

E. Chemical and Petrochemical Industry

The B30B heat exchanger is extensively used in the chemical and petrochemical industry for various heat exchange processes. It facilitates efficient cooling, condensation, and evaporation of chemicals, ensuring optimal process conditions. Its ability to handle corrosive fluids and high temperatures makes it a reliable choice for demanding applications.

V. Case Studies: Success Stories of Gasketed Plate Heat Exchanger B30B

A. Energy Savings Achieved in a Commercial Building

In a commercial building, the installation of B30B heat exchangers in the HVAC system resulted in significant energy savings. The high thermal efficiency and compact design allowed for better heat transfer and reduced energy consumption. The building's operating costs were considerably lowered, demonstrating the effectiveness of the B30B in energy-saving applications.

B. Increased Efficiency in a Power Plant

A power plant incorporated B30B heat exchangers for heat recovery from flue gases. By utilizing the waste heat, the plant's overall efficiency was improved, reducing fuel consumption and emissions. The B30B's ability to handle high temperatures and corrosive gases made it an ideal choice for this demanding application.

C. Heat Recovery in a Food Processing Plant

A food processing plant implemented B30B heat exchangers to recover heat from hot water streams. The recovered heat was used to preheat incoming water, reducing the energy required for heating. This resulted in substantial energy savings and a more sustainable operation.

VI. Installation and Maintenance Considerations

A. Proper Sizing and Selection of Gasketed Plate Heat Exchanger B30B

To ensure optimal performance, it is essential to properly size and select the B30B heat exchanger based on the specific application requirements. Factors such as flow rates, temperature differentials, and pressure drops need to be considered during the design phase. Consulting with heat exchanger experts and following manufacturer guidelines is crucial for achieving the desired energy-saving benefits.

B. Installation Guidelines and Best Practices

During installation, it is important to follow the manufacturer's guidelines and best practices to ensure proper functioning of the B30B heat exchanger. This includes proper alignment of the plates, correct gasket installation, and appropriate tightening of the frame bolts. Adequate clearance should be provided for maintenance and cleaning purposes.

C. Routine Maintenance and Cleaning Procedures

Regular maintenance and cleaning are essential for maintaining the efficiency of the B30B heat exchanger. Routine inspections should be conducted to check for fouling or scaling on the plates. Cleaning procedures, such as chemical cleaning or mechanical methods, should be performed as needed. Gaskets should be inspected and replaced if damaged or worn out to maintain a tight seal.

Conclusion

The gasketed plate heat exchanger B30B offers a wide range of benefits and advantages, making it the best choice for energy-saving heat exchange applications. Its high thermal efficiency, compact design, and versatility make it suitable for various industries and processes. By reducing energy consumption, optimizing heat recovery, and enhancing overall system performance, the B30B contributes to significant cost savings and environmental sustainability. As technology continues to advance, we can expect further developments and innovations in gasketed plate heat exchanger B30B, solidifying its position as the go-to solution for energy-efficient heat exchange.

Jiangsu Yuanzhuo Equipment Manufacturing CO., LTD.is also simply known as YOJO. Members of YOJO are the specialists who have gained rich experience in the heat transfer sector for many years and are holding the most advanced technology for the plate heat exchanger: research, design and manufacture.

Welcome to work with YOJO, we will provide the gasketed plate heat exchanger B30B solution for your specific needs.

E-mail:zy@jsyuanzhuo.com