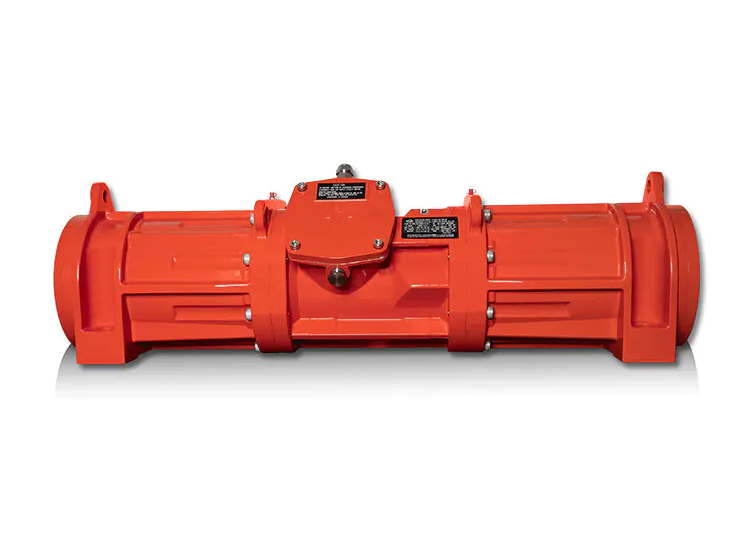

In today’s energy-conscious environment, coal plants are under increasing pressure to improve efficiency and reduce waste. One often-overlooked technology that contributes to sustainability is the use of the Coal Plants Vibrator and Coal Conveying Vibrator. By promoting consistent coal flow and minimizing interruptions, vibration systems can help lower energy consumption and emissions by reducing inefficiencies.

When coal flow is uneven, conveyors and crushers may operate below their design point or experience surges. These irregularities force downstream equipment to consume more energy per ton of coal processed. By using a Coal Plant Vibrator within storage bunkers or feed bins, operators ensure that coal discharges in a steady, predictable way, avoiding surges or blockages that waste power.

Similarly, a Coal Conveying Vibrator placed at critical transfer points along the coal handling line can mitigate material hang-up. This maintains continuous transport and reduces idle times where machinery might otherwise spin without load. Smoother operation means fewer start-stop cycles, which translates into lower electrical peaks and better energy utilization.

Adjustability is another major advantage. Modern vibration motors allow tuning of amplitude and frequency so that the force applied matches the current coal flow conditions. If coal moisture changes or the feed rate fluctuates, the vibration settings can be optimized in real-time, thereby reducing wasted force and unnecessary vibration. Suppliers like Shenzhen Putian Vibration Motor Co., Ltd. design their motors precisely for this flexibility.

Moreover, consistent flow reduces the risk of dust accumulation, which can lead to inefficient combustion or handling. By ensuring coal is transported without buildup, less fine coal is lost or degraded, which means more of the resource is utilized and less is wasted.

The environmental benefits also extend to maintenance. Less bridging and fewer manual interventions reduce the need for manual clearing, which can expose workers to dust and hazardous conditions. Longer intervals between interventions also mean reduced consumption of replacement parts and lower disposal of worn components.

In sum, the integration of both a Coal Plants Vibrator and a Coal Conveying Vibrator supports more sustainable coal plant operations by stabilizing flow, reducing energy peaks, minimizing waste, and enhancing safety. Companies such as Shenzhen Putian Vibration Motor Co., Ltd. help make these gains feasible by providing vibration motor solutions that are efficient, durable, and adaptable to varying operational conditions.