Behind every sleek car silhouette and precision-fitted panel lies a crucial piece of engineering—car body moulds. These specialized tools shape the exterior and structural components of vehicles, making them fundamental to automotive manufacturing. Whether for mass production or custom builds, understanding car body moulds reveals how form meets function on the assembly line.

What Are Car Body Moulds?

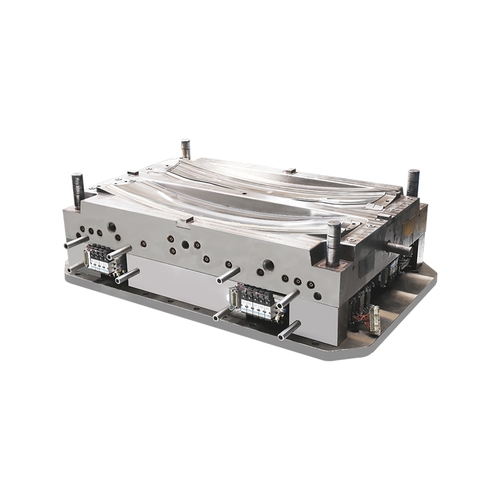

Car body moulds are precision-engineered tools used to form materials like sheet metal, fiberglass, or carbon fiber into specific car parts—such as hoods, fenders, doors, and bumpers. They act as the negative shape, ensuring each component is replicated with exact consistency in size, curve, and detail.

How Are They Used in Manufacturing?

In production, raw material is placed into the mould and shaped using pressure and heat (for composites) or stamping (for metal). Automated systems often integrate these moulds into high-speed production lines, enabling rapid, accurate fabrication of thousands of identical parts—critical for quality control and assembly efficiency.

What Materials Are Used to Make Moulds?

Most high-volume car body moulds are crafted from hardened steel or aluminum for durability and heat resistance. For prototyping or low-volume production, resins, epoxy, or silicone moulds may be used. The choice depends on production volume, part complexity, and required surface finish.

Can Moulds Be Customized for Designs?

Absolutely. Custom car body moulds are essential for concept cars, aftermarket modifications, and specialty vehicles like race or restoration models. Advanced CAD design and CNC machining allow manufacturers to create highly detailed, one-of-a-kind moulds that bring innovative or retro designs to life.

How Do You Maintain Mould Longevity?

Regular cleaning, proper storage, and protective coatings prevent rust and wear. Inspecting for surface damage and performing timely repairs ensure consistent output. Well-maintained moulds can last for hundreds of thousands of cycles, reducing long-term production costs.

From luxury sedans to rugged off-roaders, car body moulds play a silent but vital role in shaping the vehicles we drive. As automotive design evolves with lightweight materials and bold aesthetics, these moulds continue to advance—driving innovation one precise curve at a time. Whether you're in auto manufacturing or custom fabrication, investing in high-quality car body moulds means investing in precision, efficiency, and style.