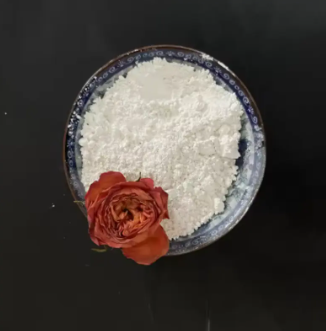

Folic acid raw material is the core raw material of vitamins, and its synthesis process optimization is the key proposition of technological upgrading in the pharmaceutical industry. How to break through the efficiency and purity limitations of the traditional synthesis path through process innovation has become the core direction to enhance industrial competitiveness.

The traditional synthetic route has the problems of many reaction steps and low yield. The traditional process of global chemical folic acid bulk drug involves multi-step organic synthesis, and each step needs to purify the intermediate, resulting in a total yield of less than 50%. The new continuous flow synthesis technology realizes the integration of reaction, separation, and purification through a microchannel reactor, reduces the transfer loss of intermediates, increases the total yield to over 75%, and shortens the production cycle by 30%.

Innovation of the catalytic system is the core of improving reaction efficiency. In the synthesis of global chemical folic acid raw materials, transition metal catalysts are often used to control the stereoselectivity of key steps. Using palladium catalyst modified by chiral ligands, the enantiomeric excess of key intermediates can be ≥99%, and the formation of by-products can be reduced. Solvent-free enzyme catalysis technology uses lipase to promote the transesterification reaction, completes high selectivity synthesis under mild conditions, and reduces energy consumption and waste discharge.

Process control technology ensures process stability. Online infrared spectroscopy is used to monitor the reaction process in real time, and the reaction endpoint is judged by the change of the characteristic absorption peak to avoid degradation caused by overreaction. The intelligent feedback system automatically adjusts the catalyst dosage and reaction temperature according to the characteristics of raw materials to ensure the quality consistency between batches.

Substitution of green solvent reduces environmental load. In the synthesis of global chemical folic acid raw materials, traditional organic solvents such as dichloromethane have the problem of volatile organic compounds emission. Using ionic liquid or supercritical carbon dioxide as the reaction medium can realize solvent-free synthesis and improve the reaction rate at the same time; The solvent recovery system realizes solvent recycling through distillation-membrane separation coupling technology, reducing the consumption of fresh solvent by more than 40%.

Accurately control impurities to improve product purity. Isomers and residual catalysts that may be produced in the synthesis process need to be accurately removed by high-performance chromatography separation technology. Global chemical Folic acid raw materials with purity ≥99.5% can be separated by simulated moving bed chromatography through continuous injection and elution. High-resolution mass spectrometry monitoring technology can identify and quantify trace impurities and guide process optimization to reduce impurity generation.

To sum up, the folic acid bulk drug has achieved breakthrough optimization of the synthesis process through continuous flow synthesis, catalytic system innovation, process control, green solvent substitution, and impurity control. This technological innovation, which focuses on the synthesis process, not only improves the production efficiency and product purity, but also promotes the global chemical folic acid raw material medicine industry to upgrade to an efficient, green, and intelligent direction, providing a reproducible technical paradigm for the production of vitamin raw materials.

How to optimize the synthesis process of the global chemical folic acid bulk drug?