If you're involved in manufacturing, you've likely heard the term Stamping Mold. But what goes into one, and why does the choice of a Stamping Mold Manufacturer matter so much for your production line? Let's break this down from a practical perspective.

A Stamping Mold is essentially a specialized tool used to shape or cut metal sheets into specific forms. Think of everyday items like car brackets, electronic enclosures, or appliance components—many of these are made using a Stamping Mold. The process involves placing a metal blank into the mold, which then presses down with significant force to create the desired part. This method is popular because it allows for rapid, consistent production once the tooling is set up. However, the quality of the end part is deeply tied to the design and craftsmanship of the Stamping Mold itself. This is where the role of a skilled Stamping Mold Manufacturer becomes clear. They don't just supply a tool; they provide a solution that affects your entire output.

So, what should you look for in a Stamping Mold Manufacturer? Experience and adaptability are key. A good manufacturer will discuss your project needs—such as material type, part complexity, and production volume—before suggesting a mold design. For instance, if you're producing high-volume automotive parts, the Stamping Mold needs to be durable enough to withstand millions of cycles without wearing out. The right Stamping Mold Manufacturer will use robust materials and precision machining to meet this demand. They also consider factors like ease of maintenance and how the mold integrates with your existing presses. It's a collaborative process aimed at avoiding downtime and ensuring smooth operations.

Beyond the initial build, a reliable Stamping Mold Manufacturer often offers support with troubleshooting and minor adjustments. Since molds can require fine-tuning after installation, having a partner who understands the nuances of stamping can save you time and resources. Whether you're prototyping a new component or scaling up production, the relationship with your Stamping Mold Manufacturer influences not just part quality, but also long-term efficiency. By focusing on clear communication and practical needs, you can leverage a Stamping Mold to support consistent, cost-effective manufacturing.

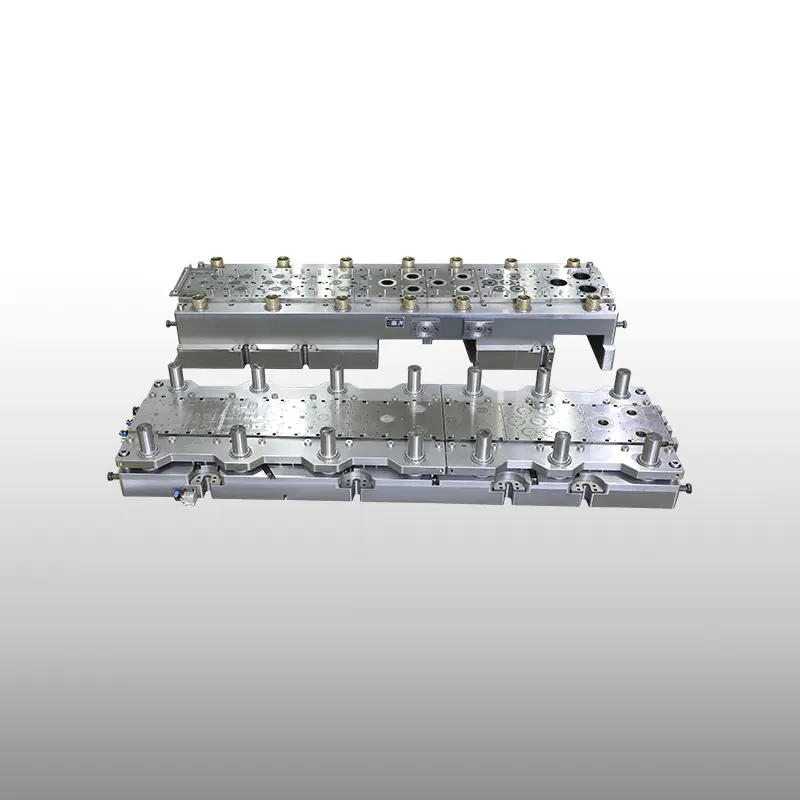

Specification Parameters

| Comprehensive life: | ≥160 million punches |

| Blade die life: | ≥5 million strokes/0.1mm |

| Mold structure: | Three-plate mold base + ball guide |

| Effective cutting edge height: | ≥8mm |

| Blade material: | DJ40 |

| Grooved die form: | Punch grooved die, slow wire finishing, the punch is polished using a special process to remove the oxidation layer |

| Guide parts: | Precision + high hardness |

| Blanking speed during running-in period: | 80-280 punches/minute |

| Blanking speed: | 280-300 punches/minute |

| Concentricity: | ≦0.05mm |

| Protection device: | Equipped with misfeed protection device |

| Punching burr: | ≦0.05mm |

| Riveting force: | 30N |

| Safety device: | Misfeed detection + equal height limit column |

| Product output form: | Conveyor belt Rotor control device Chute control device |

| Plate control device: | Cylinder |

| Mold base material: | Upper and lower mold seats P20, middle unloading seat P20, the second and fourth levels are made on the same set of molds and are interchangeable during production. The shaft hole can be used for three interchangeable pumping plates. |

| Spare parts provided: | 30% of wearing parts |

| Internal plate material: | Cr12MOV |

https://www.motorcoremold.com/product/