In the fast-paced world of modern packaging, precision and efficiency are key to maintaining product quality and meeting high production demands. The SANTUO high speed wrap around labeling machine is designed to deliver exceptional labeling accuracy for bottles, cans, and cylindrical containers across various industries. From food and beverages to pharmaceuticals and cosmetics, this machine ensures that every product is labeled perfectly, enhancing brand presentation and consumer trust.

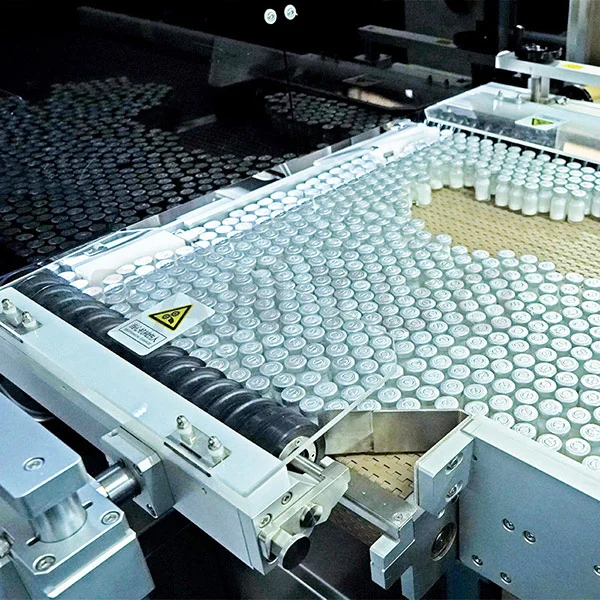

1. Smooth and Safe Bottle Feeding System

A critical feature of the high speed wrap around labeling machine is its advanced feeding conveyor belt, engineered to ensure smooth product flow. Unlike conventional labeling systems that can cause bottle jams, squeezing, or breakage, this machine’s conveyor system provides:

-

Gentle product handling: Prevents excessive pressure that could damage bottles

-

Reduced downtime: Minimizes labeling interruptions caused by product blockages.

-

Consistent alignment: Ensures bottles enter the labeling station in the correct position for maximum accuracy.

This technology helps manufacturers maintain high-quality output while reducing waste from damaged packaging.

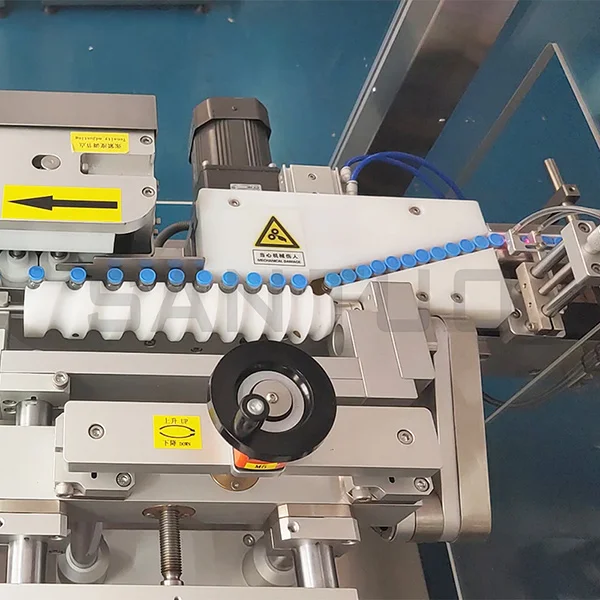

2. Integrated Bottle Removal Device for Damage Prevention

The machine is equipped with a bottle removal mechanism that automatically separates defective or misaligned bottles before labeling. This feature not only prevents damage during the labeling process but also:

-

Reduces rejection rates: Ensures only properly positioned bottles enter the labeling stage.

-

Improves product consistency: Eliminates the risk of labels being applied to damaged or irregular bottles.

-

Protects downstream processes: Prevents faulty products from reaching filling or capping stages.

By preventing costly damage and product loss, this system significantly improves operational efficiency and profitability.

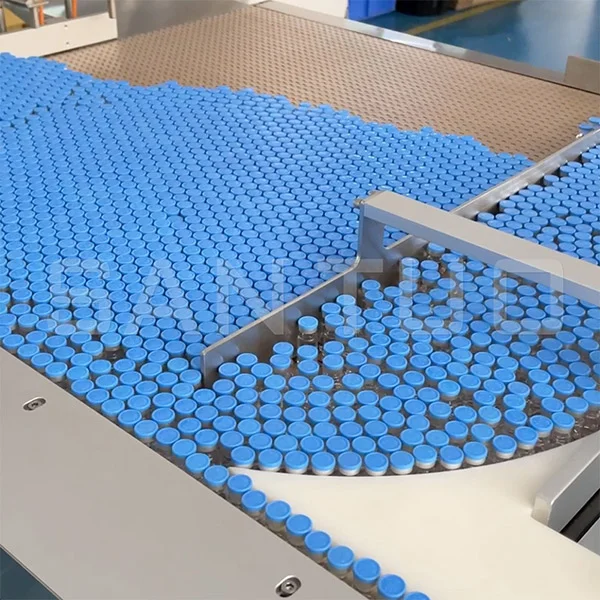

3. Multi-Bottle Type Compatibility with Minimal Changeovers

One of the standout advantages of the high speed wrap around labeling machine is its ability to handle multiple bottle types with minimal adjustment. The replacement of specification parts is rare, which means:

-

Cost savings: Fewer spare parts are needed, lowering maintenance expenses.

-

Time efficiency: Quick-change components allow operators to switch bottle formats rapidly.

-

Versatility: Suitable for labeling different container shapes and sizes without sacrificing accuracy.

For manufacturers producing multiple SKUs or seasonal product variations, this flexibility translates into faster production turnaround and better market responsiveness.

4. Enhanced Production Efficiency and Cost Savings

Every feature of the high speed wrap around labeling machine is designed to maximize productivity. The combination of smooth bottle feeding, automatic defect removal, and fast format changes results in:

-

Higher output rates: Capable of labeling thousands of containers per hour.

-

Lower labor requirements: Reduced need for manual inspection and adjustments.

-

Optimized resource usage: Minimal waste of labels, adhesive, and packaging materials.

By streamlining operations, businesses can meet growing market demand without increasing operational costs.

5. Applications Across Industries

Thanks to its precision and speed, the high speed wrap around labeling machine is widely used in:

-

Food & Beverage: Bottled water, soft drinks, beer cans, condiments, and sauces.

-

Pharmaceuticals: Medicine bottles, syrups, and health supplements.

-

Cosmetics & Personal Care: Lotion bottles, shampoo containers, and skincare packaging.

-

Household Products: Cleaning solution bottles, air freshener cans, and specialty sprays.

No matter the industry, the machine’s adaptability ensures consistent, professional labeling.

6. Designed for Long-Term Reliability

Built from high-quality materials and incorporating advanced automation controls, the high speed wrap around labeling machine delivers long-lasting performance. Operators benefit from:

-

User-friendly interface: Easy to operate, even for less experienced staff.

-

Durable components: Resistant to wear and designed for continuous operation.

-

Low maintenance requirements: Keeps the machine running at peak efficiency with minimal downtime.

Conclusion

The high speed wrap around labeling machine represents the perfect balance between speed, accuracy, and flexibility. With its gentle bottle handling system, automatic defect removal, and compatibility with multiple bottle types, it offers a highly efficient solution for modern packaging lines. Manufacturers can enjoy higher productivity, reduced waste, and improved product presentation—giving them a competitive edge in their industry.