The automotive industry depends on efficient, reliable, and precise welding systems to maintain production flow. Choosing the right supplier is a strategic decision, as the quality of welding equipment influences output, safety, and long-term operating costs. When comparing a Dizo automotive welder supplier with other global welding equipment providers, there are clear differences in focus, support, and adaptability that matter to manufacturers.

Why Welding Suppliers Matter in Automotive Production

Welding is more than a mechanical task in car manufacturing. It is a core process that connects structural components, ensures safety, and supports efficiency in high-volume production. An automotive welder supplier affects outcomes in three ways:

-

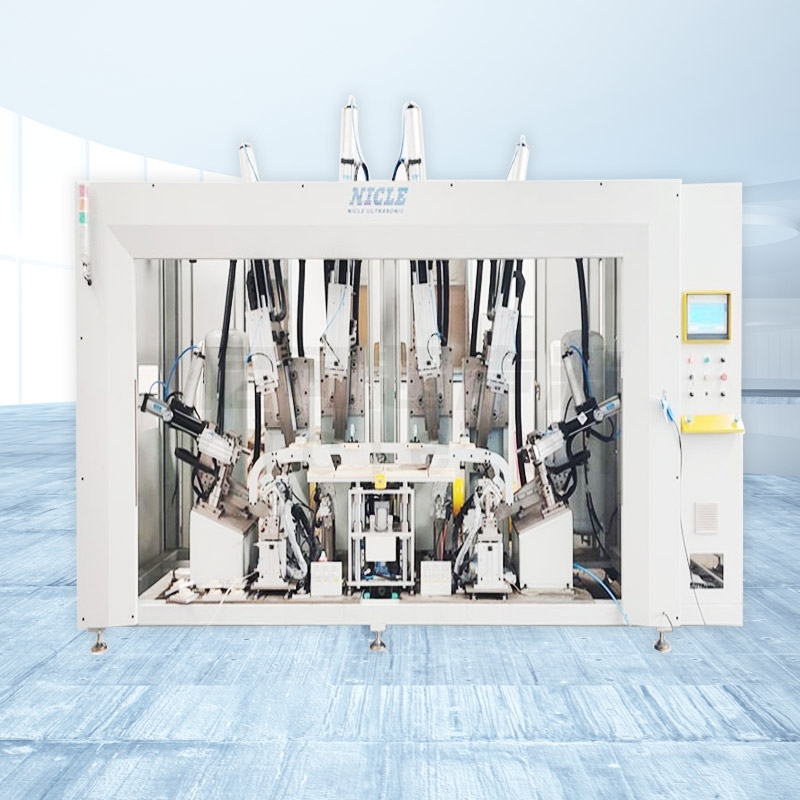

Technology – modern welding equipment incorporates automation, robotics, and monitoring systems.

-

Reliability – equipment breakdowns cause costly downtime.

-

Support – training, maintenance, and technical advice improve long-term performance.

Comparing suppliers helps manufacturers decide which partner aligns with their production goals.

Key Global Welding Equipment Providers

There are several well-established global suppliers known for their welding systems in automotive and heavy industry. Some of the major names include:

-

Lincoln Electric – based in the United States, with a wide range of industrial welding products.

-

Fronius – an Austrian company recognised for advanced welding technology and energy-efficient systems.

-

ESAB – a Swedish-American supplier offering global coverage with diverse welding solutions.

-

Panasonic Welding Systems – part of Panasonic, focusing on robotic welding solutions for automotive.

-

Miller Electric – another US-based provider known for reliability and innovation in welding equipment.

These companies have decades of global market presence and broad distribution networks. However, global scale can sometimes mean less customised attention for individual automotive manufacturers.

How a Dizo Automotive Welder Supplier Differs

When looking at a Dizo automotive welder supplier, several points stand out in comparison with these global providers.

1. Specialisation in Automotive Applications

Global providers serve multiple industries, from construction to shipbuilding. A Dizo supplier, on the other hand, focuses closely on automotive welding needs. This specialisation means equipment is designed and supported with car manufacturing priorities in mind—speed, precision, and adaptability to high-volume production.

2. Flexibility and Customisation

Large global suppliers often promote standardised systems. While these are reliable, they may not be tailored to unique production requirements. A Dizo supplier is more likely to offer customised settings, adaptable welding systems, and responsive adjustments to match specific factory workflows.

3. Localised Support and Faster Response

Downtime is expensive, and waiting for overseas parts or service teams can disrupt schedules. By working with a Dizo automotive welder supplier, manufacturers benefit from local support, quicker servicing, and faster replacement cycles. This local responsiveness improves overall production efficiency.

4. Competitive Cost Structures

Global suppliers bring strong reputations but also higher overhead costs. A Dizo supplier often provides more competitive pricing without reducing quality. For manufacturers balancing budgets, this combination of affordability and reliability is attractive.

5. Long-Term Partnerships

Large suppliers may treat customers as one among thousands. A Dizo supplier builds stronger long-term partnerships, often working closely with automotive companies to improve processes, train staff, and anticipate future welding needs.

Comparing Global Scale with Local Focus

The choice often comes down to what manufacturers value most. Global providers offer:

-

Broad product ranges.

-

Recognised brand reputation.

-

Extensive research and development.

But they can also present challenges:

-

Longer lead times for parts and service.

-

Higher equipment costs.

-

Less flexibility for custom production lines.

In contrast, a Dizo automotive welder supplier provides:

-

Tailored systems for automotive use.

-

Local service and training.

-

More accessible cost structures.

The Importance of Efficiency in Modern Automotive Welding

Automotive production is moving towards lightweight materials, electric vehicle structures, and sustainable practices. Welding systems must adapt quickly to these changes. The supplier that provides flexibility, technical support, and industry-specific solutions is better positioned to help manufacturers stay efficient.

For example:

-

Lightweight alloys require advanced welding systems with precise heat control.

-

Battery enclosures for EVs need durable, leak-proof welds.

-

Sustainability targets push manufacturers to adopt energy-efficient welding solutions.

A supplier with strong automotive focus can address these needs more directly than a general global provider.

Making the Right Supplier Choice

When comparing options, manufacturers should ask:

-

Does the supplier specialise in automotive welding, or serve multiple industries?

-

How fast is their response time for service or replacement parts?

-

Can the supplier customise solutions for unique factory needs?

-

What level of training and technical support is included?

-

Are cost structures competitive without sacrificing quality?

A Dizo automotive welder supplier provides positive answers to these questions, making them a strong choice for companies that value production efficiency and adaptability.

Final Thoughts

The right welding supplier shapes the success of automotive production. While global providers like Lincoln Electric, Fronius, ESAB, Panasonic, and Miller bring established reputations and wide offerings, they may not always deliver the flexibility or support that manufacturers need.

A Dizo automotive welder supplier stands apart with its specialisation in automotive applications, localised service, and competitive cost structures. For manufacturers aiming to improve efficiency, reduce downtime, and prepare for future industry shifts, working with a supplier that understands the unique demands of car production offers clear advantages.