In electrical design, the Conduit Gland plays a crucial role in bridging flexible conduit systems with electrical panels or enclosures. Whether installed in heavy-duty machinery or distributed across infrastructure projects, the Conduit Gland ensures secure, strain-relieved connections that maintain protection integrity against water, dust, and other external hazards.

With the growing complexity of industrial wiring schemes—particularly in sectors such as power generation, smart manufacturing, and data centers—maintaining consistent cable shielding is paramount. Conduits serve as the first layer of defense, protecting cables from crushing, pulling, and environmental damage. However, without a suitable interface, conduits cannot be securely terminated at junction boxes, risking exposure and mechanical strain at entry points.

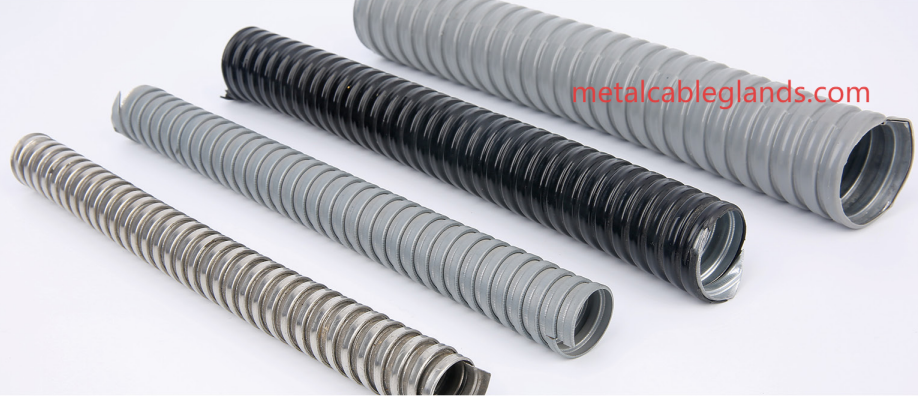

Zhejiang Hongjuesi Connectors (HJSI), a trusted supplier of cable connection and sealing components, offers a diverse range of conduit glands designed for metallic and non-metallic conduit types. These glands are engineered to provide a seamless mechanical and environmental seal between conduit ends and the receiving panel or equipment body. Available in various materials, HJSI’s conduit glands are adaptable to both indoor and outdoor installations, including high-vibration, high-humidity, and corrosive settings.

In manufacturing plants, for instance, motor control systems often require conduits for routing power and signal cables across moving or rotating equipment. HJSI's metal conduit glands provide enhanced clamping strength and IP-rated sealing, which reduces the risk of cable fatigue, loosening, or contamination due to oils and dust.

Likewise, smart building infrastructure benefits from the use of conduit glands to support reliable cable containment in HVAC systems, lighting control, and fire alarm lines. In these environments, using a flame-retardant and UV-stabilized gland is essential to meet safety regulations and maintain operational reliability over time. HJSI’s nylon and brass variants offer thermal stability and are compliant with major international standards.

One of the advantages of HJSI conduit glands is their ease of integration into new and retrofit projects. With modular locking features and standardized thread options (PG, NPT, and metric), these glands ensure compatibility with conduits and cabinets from multiple manufacturers. For installers, this means faster assembly and less time spent sourcing or modifying components on-site.

In transportation networks—such as rail systems or smart traffic installations—long conduit runs require consistent protection at every enclosure junction. HJSI’s stainless-steel conduit glands are corrosion-resistant and ideal for outdoor or underground installations exposed to rain, road salts, or temperature swings. The secure locking mechanism also reduces the risk of conduit disconnection due to vibration or accidental impacts.

What truly sets HJSI apart is their commitment to quality manufacturing and customer support. Every product undergoes strict testing to verify mechanical load tolerance, temperature range, and sealing performance. Their technical team also provides recommendations for material selection, torque application, and enclosure compatibility, ensuring the right solution is applied in every project scenario.

Engineers, electrical contractors, and procurement teams across industrial and infrastructure sectors continue to rely on HJSI for dependable and cost-effective conduit gland solutions. Their focus on adaptability, safety, and performance makes them a leading choice for conduit termination in both standard and demanding applications.For a full overview of available Conduit Gland options and technical support from Zhejiang Hongjuesi Connectors, please visit: https://www.metalcableglands.com/product .