A Closer Look at the Materials Behind Inflatable Boat Fabric Performance

Inflatable Boat Fabric is built on a foundation of specialized materials designed to manage the demands of real-world marine use. Whether used for recreation, rescue, or transport, the fabric's performance depends heavily on how well its components are selected and layered. The right combination of base cloth and coating makes a noticeable difference in flexibility, durability, and air retention.

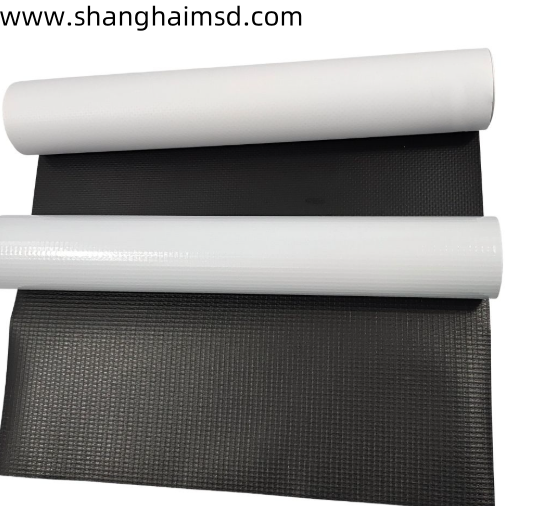

Typically, inflatable boat fabric uses a polyester or nylon base that is coated with PVC or another synthetic layer. The weave of the base cloth affects tear resistance, while the coating helps with waterproofing and UV protection. A tight weave structure offers added support under high pressure, especially when inflated for extended periods. In challenging weather, that extra stability can be valuable.

jtpackage focuses on creating inflatable boat fabric with strong layering techniques that enhance bonding between textile and coating. This bond ensures that the material stays sealed under frequent folding, stretching, and exposure to water. By optimizing the heat-sealing and lamination processes, jtpackage helps users gain better long-term usage without frequent material fatigue.

Another important aspect is how the material handles environmental factors. Inflatable boats often stay exposed to sunlight, saltwater, and air temperature changes. The right fabric blend helps reduce cracking, delamination, or shrinkage, extending both appearance and usability. Testing each material batch before production ensures consistent performance across different use cases.

If you're looking to understand what goes into dependable inflatable boat fabric, it’s helpful to consider both the raw materials and the process behind it. For more information and available options from jtpackage, visit

https://www.shanghaimsd.com/product/