In the intricate ecosystem of motion control and mechanical transmission, planetary reducers play a pivotal role. These compact, efficient, and high-torque gear systems are widely used in industries ranging from robotics and automation to CNC machinery and aerospace. However, with many variations in size, performance, and configuration, selecting the right planetary reducer for your application can be challenging.

As a company deeply rooted in transmission component development, technical consultation, and customer-centric service, Yijiaang has built a reputation for guiding clients through these complex decisions with precision and professionalism. In this article, we explore the key aspects of planetary reducers—from their working principles to practical selection tips—and how Yijiaang helps businesses implement them successfully.

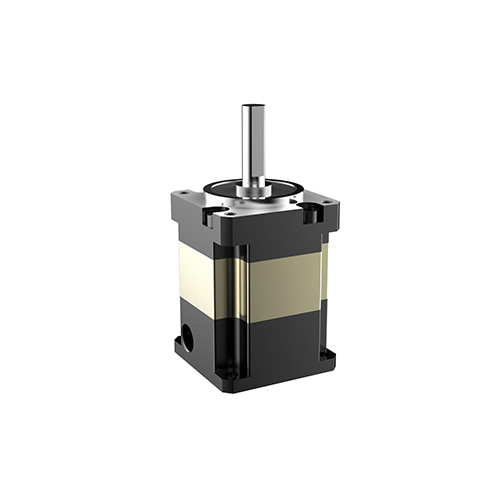

What is a Planetary Reducer?

A planetary reducer (also known as a planetary gearhead or gearbox) is a mechanical device designed to reduce the speed of an input shaft while increasing torque output. It features a unique internal design consisting of:

Sun Gear: The central gear connected to the input shaft.

Planet Gears: Multiple gears rotating around the sun gear.

Ring Gear: The outer casing with internal teeth that mesh with the planet gears.

Carrier: Holds the planet gears in position and delivers output torque.

This configuration results in a compact, balanced, and highly efficient system capable of handling high torque loads with minimal backlash and excellent transmission accuracy.

Key Advantages of Planetary Gearboxes

High Torque Density: Due to even load distribution among planet gears.

Compact Size: High performance in a small footprint.

Precision: Low backlash makes them ideal for applications requiring high positional accuracy.

High Efficiency: Usually over 95%, depending on the number of stages.

Durability: Capable of handling shocks and high dynamic loads.

Where Planetary Reducers Are Used

Planetary reducers are versatile and are often found in:

Robotics and automation arms

CNC machines and 3D printers

Packaging and labeling machinery

Conveyor systems

Medical imaging equipment

Aerospace and satellite systems

Electric vehicles and AGVs

These applications demand smooth motion control, space efficiency, and precision—all characteristics of planetary gearing.

How to Choose the Right Planetary Reducer: A Practical Guide

When selecting a planetary reducer, Yijiaang’s experts recommend considering the following key factors:

1. Torque Requirements

Choose a reducer that can handle the peak and continuous torque of your system. Undersizing may lead to overheating and premature wear.

2. Gear Ratio

The gear ratio determines speed reduction and torque multiplication. Typical planetary reducers offer ratios from 3:1 up to 100:1 or higher, often in multiple stages.

3. Backlash

Low-backlash models are essential for positioning applications like robotics or precision cutting tools. Standard industrial applications may tolerate higher backlash levels.

4. Efficiency

High-efficiency gearboxes minimize energy loss. For applications with long duty cycles or high-speed operation, this can significantly reduce operating costs.

5. Mounting Type and Interface

Compatibility with your motor (flange type, shaft size) is crucial. Yijiaang offers customizable mounting interfaces and modular designs for easy integration.

6. Environment

Consider ambient temperature, dust, moisture, and vibration levels. Yijiaang provides IP-rated and sealed models for harsh or specialized environments.

Yijiaang’s Expertise in Planetary Transmission Systems

With years of experience in the motion control and mechanical transmission space, Yijiaang is not just a supplier but a technical partner for businesses looking to implement planetary gear solutions.

Here’s what sets Yijiaang apart:

Custom Engineering: Whether it’s a unique mounting configuration, material requirement, or torque specification, Yijiaang can design tailor-made gearboxes.

System Matching Support: Yijiaang offers one-on-one consulting to help customers match reducers with motors, controllers, and load profiles.

Technical Services: On-site support, performance testing, and maintenance training are all part of Yijiaang’s service portfolio.

Rapid Delivery & Global Reach: With streamlined logistics and international service networks, Yijiaang ensures fast and reliable product delivery.

Maintenance and Longevity Tips

To ensure optimal performance and service life of your planetary reducer:

✅ Check alignment regularly during installation and operation.

✅ Lubricate according to manufacturer guidelines (most models are pre-lubricated for life, but some require periodic oil changes).

✅ Avoid overload conditions beyond rated torque.

✅ Keep the reducer clean and cool, especially in dusty or high-temperature environments.

Yijiaang provides detailed manuals and technical documentation for each product line, ensuring customers can operate and maintain equipment confidently.

Future Trends in Planetary Reducers

As smart automation, AI, and green technologies evolve, the planetary reducer market is shifting toward:

Integrated mechatronic systems (combining motors, reducers, and encoders)

Lighter, more compact gearheads for mobile robotics

Digital monitoring (IoT-enabled reducers for predictive maintenance)

Eco-friendly lubricants and materials

Yijiaang is actively investing in these innovations to provide next-generation transmission solutions that are smarter, more efficient, and environmentally conscious.

Conclusion

Planetary reducers are the unsung heroes of modern motion control systems—quietly powering machines, robots, and vehicles with precision and reliability. Whether you're designing a robotic arm, a conveyor line, or an advanced piece of automation equipment, selecting the right gearbox is key.

With its technical expertise, product variety, and customized support, Yijiaang stands ready to guide you through every phase—from selection to successful implementation. Let their transmission expertise help power your next innovation.

Exploring the Characteristics of Planetary Reducers: Efficiency and Precision