In modern industrial production, achieving high-quality emulsions, dispersions, and homogenized mixtures is essential across various industries, including pharmaceuticals, cosmetics, food, and chemicals. A key piece of equipment that facilitates this process is the vacuum emulsifying homogenizer mixer. This advanced mixing technology ensures consistent product quality, improved efficiency, and enhanced stability in manufacturing processes.

What is a Vacuum Emulsifying Homogenizer Mixer?

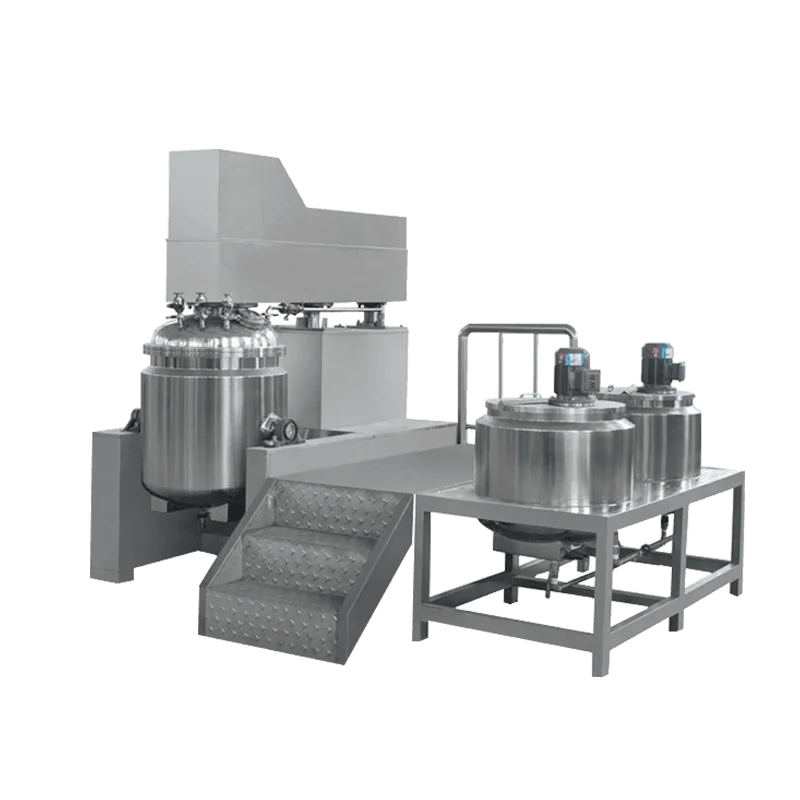

A vacuum emulsifying homogenizer mixer is a specialized piece of equipment designed to create stable emulsions and homogeneous mixtures by combining multiple phases—such as oil and water—under vacuum conditions. The system typically consists of a main emulsification tank, a homogenizing unit, a vacuum pump, heating and cooling systems, and control mechanisms.

Key Functions and Benefits

1. Enhanced Emulsification and Homogenization

The high-shear homogenizing head breaks down particles to the micron or nanometer level, ensuring a fine and stable emulsion. This is particularly crucial in industries like cosmetics, where creams and lotions must maintain smooth textures and long-term stability.

2. Vacuum Function for Air-Free Mixing

By creating a vacuum environment, the system effectively removes air bubbles, preventing oxidation and enhancing product purity. This is essential for pharmaceutical and food applications where product integrity is critical.

3. Improved Production Efficiency

Vacuum emulsifying homogenizers integrate multiple processes, such as mixing, dispersing, heating, cooling, and de-aerating, into one system. This streamlines production, reduces processing time, and enhances batch consistency.

4. Customization for Various Applications

Industries such as pharmaceuticals, cosmetics, food, and chemicals require tailored mixing solutions. Vacuum emulsifying homogenizers can be customized to meet specific viscosity, temperature, and shear force requirements, making them highly versatile.

Applications Across Industries

Cosmetics: Creams, lotions, serums, and foundations

Pharmaceuticals: Ointments, gels, and medicinal emulsions

Food Processing: Sauces, mayonnaise, and dairy-based products

Chemical Industry: Paints, coatings, and adhesives

Orisun: A Trusted Manufacturer of Mixing Equipment

For companies seeking high-quality vacuum emulsifying homogenizer mixers, Orisun is a reliable partner specializing in mechanical design and manufacturing. Orisun provides cutting-edge solutions tailored to the needs of various industries, ensuring efficiency, durability, and precision in production processes. With a strong commitment to innovation and customer satisfaction, Orisun delivers equipment that meets the highest industry standards.

Conclusion

Vacuum emulsifying homogenizer mixers are indispensable tools in modern industrial production, ensuring high-quality emulsions, increased efficiency, and enhanced product stability. Whether in the pharmaceutical, cosmetics, food, or chemical industry, investing in advanced mixing technology from a trusted Orisun manufacturer can optimize production and drive business success.

Understanding the Vacuum Emulsifying Homogenizer Mixer: Industrial Applications and Benefits