In the ever-evolving landscape of manufacturing, the quest for efficiency, precision, and innovation remains paramount. One of the most significant advancements in this realm is the development of mask blank body making machines. These sophisticated devices play a crucial role in the production of semiconductor masks, which are essential for the fabrication of integrated circuits and other electronic components. By streamlining the manufacturing process and enhancing the quality of mask blanks, these machines are revolutionizing the way industries approach production. As technology continues to advance, the integration of automation and precision engineering in mask blank body making not only boosts productivity but also paves the way for the next generation of electronic devices, ultimately transforming the entire manufacturing landscape.

In this blog post, we will explore the significant role of mask blank body making machines in the manufacturing process, and how companies like Broadfair, a high-tech enterprise specializing in research, development, and production, have been at the forefront of this technological revolution.

What is a Mask Blank Body Making Machine?

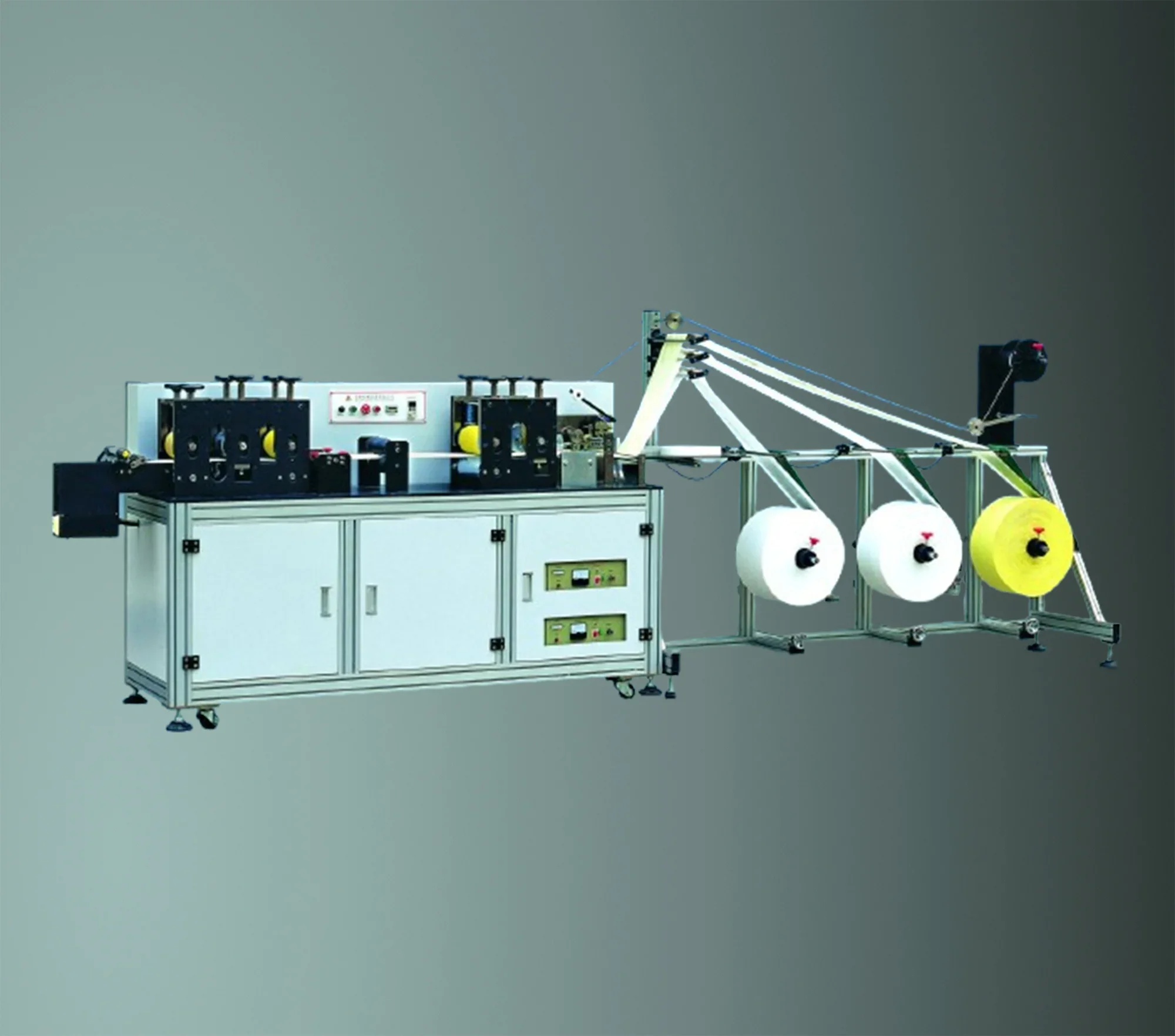

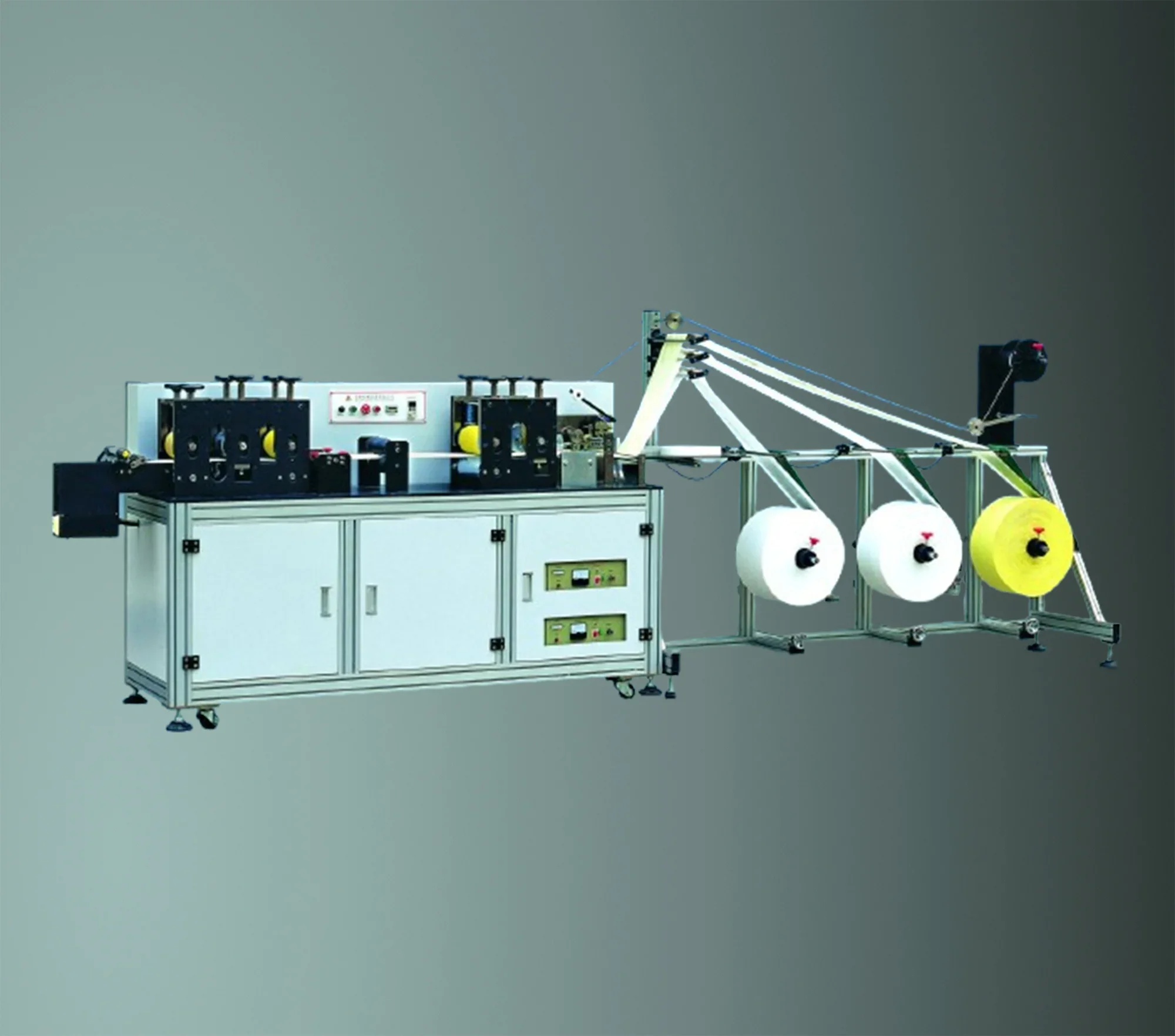

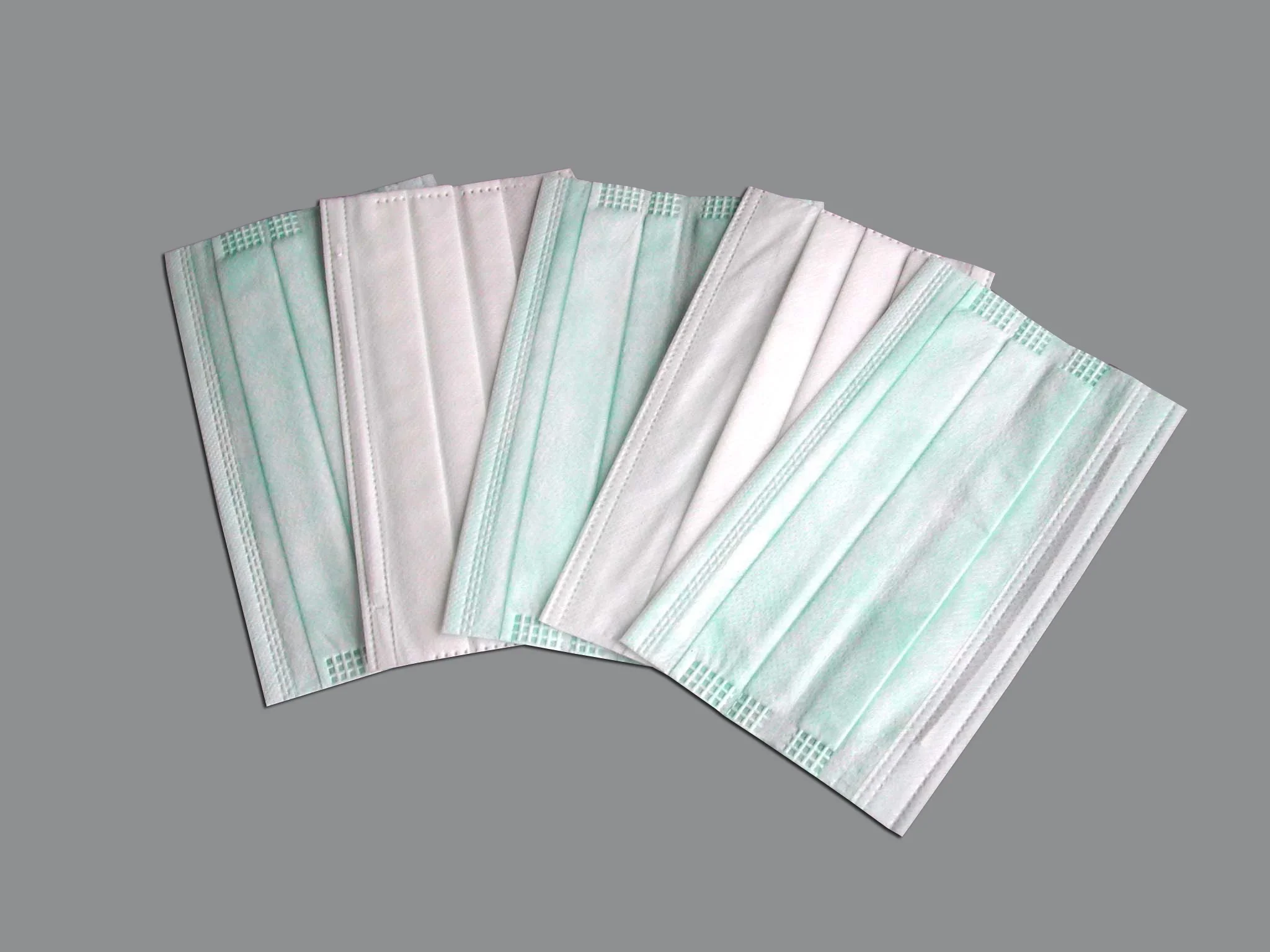

A Mask Blank Body Making Machine is a key piece of equipment used in the production of the core structure or body of face masks. This machine automates the process of forming the mask’s main body, typically composed of nonwoven fabric, which serves as the essential filter material for respiratory protection. The mask blank body produced by these machines is then further processed, with additional components such as ear loops, nose clips, and multiple layers, added through subsequent stages in the production line.

These machines typically integrate various functions, including feeding, shaping, and cutting, into a seamless process, significantly reducing the need for manual labor and increasing production efficiency. By automating the creation of mask blanks, manufacturers can produce high volumes of masks with greater consistency, accuracy, and speed, ensuring that production can scale up to meet global demand.

The Importance of Mask Blank Body Making Machines in Modern Manufacturing

The role of mask blank body making machines has become indispensable in the face mask manufacturing industry. Here are some of the key reasons why they are so important:

Efficiency and Speed: One of the primary advantages of these machines is their ability to produce mask bodies quickly and efficiently. The automated nature of these machines allows for high-speed production without sacrificing quality, which is crucial during times of increased demand. As a result, manufacturers can meet tight production schedules and distribute masks at a large scale.

Cost-Effective Production: By automating the production of mask blanks, manufacturers can significantly reduce labor costs and eliminate human error, which is common in manual processes. This makes the production process more cost-effective and allows manufacturers to focus resources on other essential parts of the mask-making process.

Consistency and Quality: Mask blank body making machines ensure that every mask blank is produced with the same dimensions and specifications. This consistency is crucial in ensuring that each mask is of the highest quality and meets regulatory standards. Masks with a consistent structure are also easier to assemble, making the overall production process smoother.

Integration with Other Production Stages: These machines often come equipped with advanced features that allow them to seamlessly integrate into broader mask production lines. For example, they can connect with machines that add ear loops or other components, ensuring that the entire process remains smooth and streamlined.

Broadfair: Leading the Charge in Mask Manufacturing Innovation

Broadfair, a high-tech enterprise known for its innovation and cutting-edge solutions, plays a vital role in the mask production industry. With years of experience in research, development, and manufacturing, Broadfair is committed to providing state-of-the-art mask blank body making machines that meet the evolving needs of the global market.

Broadfair’s Mask Blank Body Making Machines offer several benefits that set them apart from other products on the market:

Advanced Technology: Broadfair continuously invests in research and development to integrate the latest technological advancements into their machines. This includes improved automation, energy efficiency, and precision engineering, ensuring that every mask blank produced is of the highest quality.

Customizable Solutions: Understanding that different markets and industries may have varying requirements, Broadfair offers customizable solutions to meet specific production needs. Whether it's adjusting the size, shape, or material of the mask blank body, Broadfair’s machines can be adapted to meet the unique needs of each customer.

Enhanced Productivity: With Broadfair’s machines, manufacturers can produce large quantities of mask blanks with minimal downtime. The user-friendly design, easy maintenance, and fast setup times ensure that production remains smooth, reducing the potential for costly delays and maximizing overall output.

Sustainability: Broadfair is also committed to sustainability, ensuring that their machines are energy-efficient and designed with environmentally friendly practices in mind. This is essential as the manufacturing industry increasingly looks for ways to reduce its carbon footprint and minimize waste.

Global Reach: As a company with a global presence, Broadfair has established itself as a trusted partner for mask manufacturers worldwide. Their international clientele benefits from reliable support, timely deliveries, and robust after-sales service, all of which contribute to the overall success of mask production lines.

The Future of Mask Production and Innovation

As the world continues to adapt to changing circumstances, the demand for protective equipment such as face masks remains high. The mask blank body making machine industry is poised to continue evolving, with advancements in automation and material science paving the way for even more efficient and sustainable production methods.

For manufacturers, this means that investing in high-quality, innovative machinery like Broadfair’s mask blank body making machines is essential for staying competitive. As global health standards tighten and the demand for safety products persists, companies that embrace these technological advancements will be better positioned to meet the growing needs of industries, governments, and consumers alike.

Conclusion

The introduction of Mask Blank Body Making Machines has transformed the face mask manufacturing process, enabling companies to meet the rising global demand for protective masks. The role these machines play in ensuring efficiency, consistency, and scalability in production cannot be overstated. Companies like Broadfair continue to lead the way in this revolution, providing cutting-edge solutions that help businesses optimize their operations and stay ahead of the competition.

As the world moves forward, technological innovations in mask manufacturing will continue to shape the future of production, making it more efficient, sustainable, and responsive to the changing needs of industries and consumers worldwide. Investing in high-tech solutions such as Broadfair's mask blank body making machines will help manufacturers thrive in this evolving landscape.

The Benefits of Full Automatic Face Mask Making Machines in Modern Manufacturing